4D INSPEC's Application in the field of MRO

14:09 - 17/11/2021

MRO in an acronym for Maintenance, Repair, and Overhaul (or administratively – Maintenance, Repair, and Operations). Simply put, MRO is any action that helps keep or restore an item to its working condition. A wide variety of NDT, RVI, and Visual Inspection techniques can be used. Planned, Predictive, Preventative, Non-routine, and Shutdown maintenance are the main forms of overhaul.

Applications for the 4D Inspec – non-contact measurement of surface features and micro defects at micrometer level resolution:

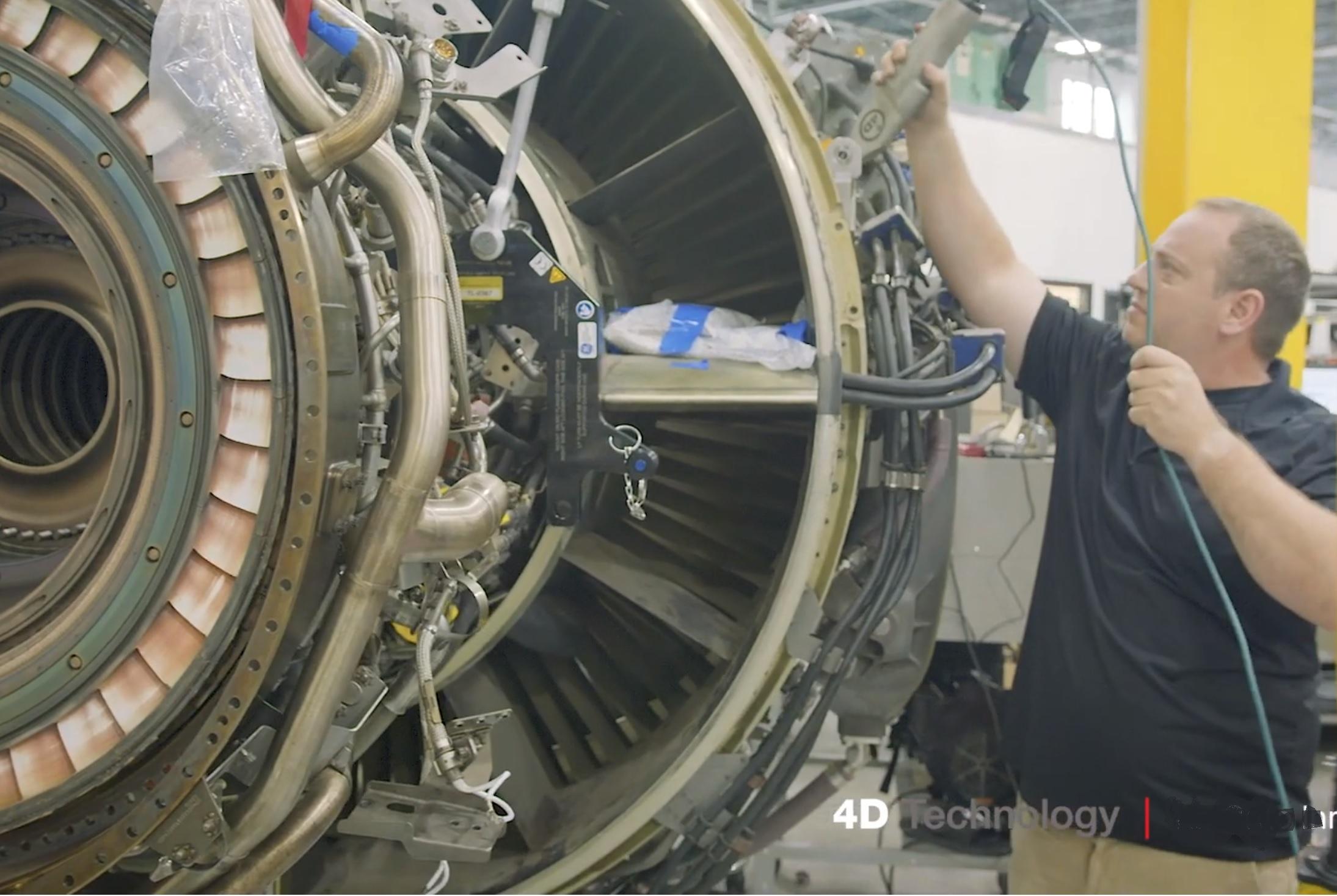

Aerospace: Aircraft Jet Engine maintenance

The 4D InSpec was designed with MRO applications in mind. Use the gauge to measure surface defects on large components such as jet engine casings and housings, directly on the part. Measure surface features/defects on components with complex geometries such as turbine blades and fir-tree roots, even blind features and holes, all with micrometer resolution.

Watch our short demonstration:

Surface defects on turbine blades and fir tree roots

Accurate measurement of surface defects on turbine blades, fir-tree roots and other structures is critical to long component life and safe operation. The 4D InSpec can instantly measure features and defects from 0.1–100 mils deep on parts with challenging geometries.

Watch our video on turbine blade edge defect measurements:

Marine Applications

4D Inspec can measure corrosion or wear at many locations on a marine vessel. The handheld portability of 4D InSpec is well-suited to measuring parts on board, in a maintenance/refit shop, or in dry dock. The 4D InSpec excels at quantifying wear and corrosion on components in situ, letting you measure with micrometer-level resolution onboard or off. Typical measurements include:

- Corrosion coupons

- Non-Slip surfaces

- Bearings and races

- Drive system components and gears

- Turbine blades and edges

Shot peen marking / engraving - micro features

Peen marking is important to parts identification requirements. The mark quality is important to quantify. If the peen marking is too shallow this reduces the longevity and durability of the identification of the parts themselves in case of wear and tear. If the peen marking is too deep this may create an ingress point for corrosion.

Difficult to quantify, each dot might be of a different depth, meaning that all the dots need to be measured. Scribe marks are equally tricky, because of variability and burrs that can be created.

Drive Train Components - micro features

The 4D InSpec brings high resolution measurement to the factory floor, making it possible to locate and measure pitting, scratches and other defects, as well as measuring dot peening, laser scribe marks, edge break and other features. 4D InSpec is more accurate than optical comparators, helping to correctly identify parts that do not meet surface texture specifications, while eliminating the waste of scrapping or reworking components that actually pass all requirements.

The 4D InSpec also excels at quantifying wear and corrosion on components during rebuilds, letting you measure with micrometer-level resolution in even the toughest environments.

Engine Components- measure fine pits, scratches, dents, corrosion

4D InSpec's can measure pits, scratches, dents, corrosion and other defects and features on large and small engine components. Measure dot peen and laser scribed markings and other fine part features as well, on shafts, mating surfaces, valves, cylinder walls, engine blocks etc.

Eliminate Replication: micro defect measurement on complex or large components

To measure defects on large or complex components inspectors are faced with limited measurement options. Handheld depth gauges are quick and portable, but they lack the resolution to make repeatable measurements. High resolution systems are typically confined to a stand in a metrology lab. In order to measure large components an inspector must make a silicone replica or rubber replica of the surface—a time-consuming, messy process.

The 4D InSpec Surface Gauge was designed to provide portable, high resolution measurement wherever it is needed on the shop floor. Its unique design allows inspectors to measure defects in corners, on radii, under flanges, and across large surfaces—effectively making replication a thing of the past. A fold mirror attachment allows measurements in extremely narrow areas or inside of bores, where even a silicone replica would prove difficult to make.

Measure Corrosion

Left unchecked corrosion can impede performance and can lead to component failure, sometimes with catastrophic results. Inspectors must be able to accurately determine corrosion severity to ensure part performance. But visual inspection is very open to interpretation, and high resolution, quantitative metrology systems are too expensive, too susceptible to vibration, and too size limited for shop use.

The 4D InSpec Surface Gauge instantaneously measure pit depth, width and volume, of all corrosion pits within the field of view. Quickly inspect corrosion over large portions of a component for a thorough, accurate assessment of the severity, even in difficult to access areas such as corners, bores and fillets.

Solar Panels: Measure solar panel roughness with 4D InSpec Surface Gauge

The 4D InSpec Surface Gauge can measure the surface texture of solar panels to ensure panel performance throughout their usable life. The handheld InSpec can accurately quantify surface roughness (Ra ~ 10-50 um) over time, and in the field, to monitor changes that could degrade panel output. The 4D InSpec is able to measure all of the glass surfaces without any influence of the underlying solar cells or traces.

The 4D Inspec is also ideal for applications such as:

- Sealing surfaces (porosity)

- Drive shafts (defects, radii)

- Washers and Bolts (defects, thread height, wear)

- Adhesives (heights, widths, voids)

- Welds (defects)

- Composites (radii, defects)

- 3D printed parts (voids, radii, roughness)

- Locomotive drive components

- Turbine blades (defects)

- Rubber seals (voids, wear)

- Bolt holes (corrosion)

- Knife blades (radii, nicks)

- Vacuum tubing (wear scars, pitting)

- Solar components (panel roughness, glass defects, trace heights)

- Bearings (defects, geometry, corner radii)

- Gears (defects, geometry)