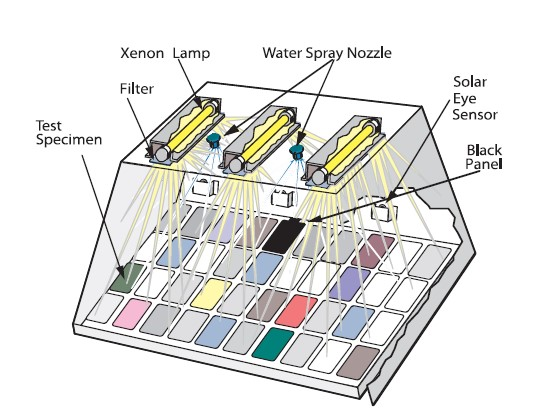

Radiant energy in the SOLARBOX is provided by a single superior air-cooled Xenon Lamp generating an irradiance level up to two times the sun one. Irradiance is the rate at which light energy falls onto the samples.

A weathering tester must control irradiance if it is to achieve accurate and reproducible test results.

SOLARBOX offers constant measurement and control of irradiance during every test, compensating for lamp and UV filter ageing via a closed loop irradiance narrow-band sensor control system.

Irradiation uniformity is guaranteed by a parabolic reflector chamber with the Xenon Lamp in the focus, the best design for a reliable flat-bed xenon exposure system and very good agreement with rotating drum xenon exposures.

TEMPERATURE CONTROL:

Temperature is another component of the end use environment which plays a key role in material degradation. Heat in the natural environment comes from the infrared portion of natural sunlight.

An object exposed to direct sunlight is always warmer than the air surrounding it. Your product is exposed in the same manner in our SOLARBOX tester.

The radiant heat received from the Xenon Lamp is continuously monitored and controlled by a B.S.T. (Black Standard Thermometer) built in the plane of test panels near your samples.

In SOLARBOX 1500e and 3000e there is the control and display of the black standard temperature between 35°C and 100°C. The importance of temperature in the weathering degradation process is that the kinetic reaction rate doubles for every 10°C temperature increase.

Consequently, because the temperature produces an accelerated ageing, it is essential to be able to control of

B.S.T. during exposure to filtered Xenon radiation.

SIMULATING THE EFFECT OF RAIN AND MOISTURE:

A flooding system for conducting weathering tests with freely selectable flooding interval is an available option for SOLARBOX 1500e and 3000e:

- water level indicator

- continuous flooding possible

- flooding intervals selectable between 1 and 999 minutes throughout the test program

- water temperature of 30°C to 50°C.

During flooding, the Xenon Lamp can be programmed on or off.

The flooding system operates with demineralised water from a closed recycling circuit so to minimize the need of demineralised water but offering the same test results of a high consumption spray system.

PVC and corrosion-resistant materials ensure long life of this tank pump system: capacity up to 50 litres

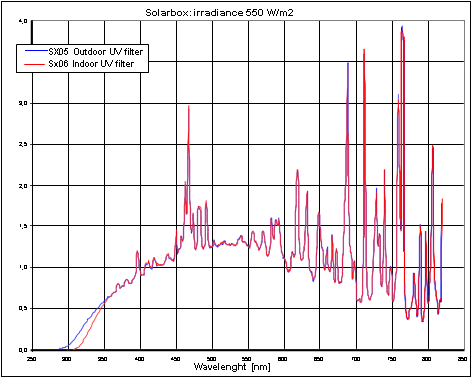

XENON LAMP AND UV FILTERS COMBINATION OPTIMIZE SUNLIGHT SIMULATION:

The SOLARBOX 1500-1500e and SOLARBOX 3000-3000e are 4 ultimate filtered Xenon light exposure and weathering instruments which simulate realistic natural outdoor weathering conditions.

The large dimensions of SOLARBOX 3000 and 3000e test chamber can accommodate 3 dimensional objects and finished industry products.

Accelerating the process requires the accurate reproduction of the sun’s rays.

The air cooled Xenon Lamp in the SOLARBOX replicates the total spectrum of the sun and not just the short wavelength UV, as we have using UVA or UVB fluorescent lamps.

Easily interchangeable light filters allow the reproduction of the specific spectral distributions found in your product’s end-use environments.

FIELDS OF APPLICATION & NORMATIVE REFERENCES:

The SOLARBOX, because of its 6 different models and a wide flexibility in available options (i.e. Humidity Control: see SOLARBOX R.H. catalogue), meets the following standards:

ADHESIVES: ASTM D904; ASTM C1442; ASTM C1501; RILEM DBS.

AUTOMOTIVE: SAE J2527; SAE J2412.

COATINGS: QUALICOAT; ISO 2135; ISO 11341; ASTM D3451; ASTM D3794; ASTM D6577; ASTM D6695; GB 1865; JIS K 5600-7-7; MPI: #113; MS

133: Part F14.

DENTISTRY: ISO 4049:2000; ISO 7491:2000.

GENERAL: IEC 68-2-9; ISO 4892-1; ASTM G151; ASTM G155.

GEOTEXTILES: ASTM D4355.

INTRA-OCULAR LENSES: ISO 11979-5:2006

INKS/PAPER: ISO 11798; ISO 12040; ISO 18909; ASTM D3424; ASTM D4303; ASTM D5010; ASTM D6901; ASTM F2366.

PACKAGING: ASTM D6551.

PHARMACEUTICAL: ICH Guideline Q1B.

PLASTICS: ISO 4892-2; JIS K 7350-2; DIN EN 513; ASTM D1248; ASTM D2565; ASTM D4101; ASTM D4459; ASTM D5071; ASTM D6662; UL 1581.

ROOFING: ASTM D4434; ASTM D4637; ASTM D4798; ASTM D4811; ASTM D5019; ASTM D6083.

RUBBER: ISO 3865; ISO 4665.

SEALANTS: ASTM C1442; ASTM C1501.

TEXTILES: AATCC TM 16; AATCC TM 169; GB/T- 8430; IS: 2454; ISO 105-B02.

Technical data:

SOLARBOX Model | 1500 | 1500e | 3000 | 3000e |

Electrical connection |

| |||

Mains voltage | 230 Vac 10%, 50/60 Hz. | |||

Mains connection | 1/N/PE | |||

Current consumption | 16 A (max.) | |||

Measures and weight | 1500 | 1500e | 3000 | 3000e |

Dimensions | 750 x 390 x 400 mm. | 890 x 390 x 400 mm. | ||

Exposure area (Horizontal Specimen Holder) | 280 x 200 mm. | 420 x 200 mm. | ||

Weight | 30 Kg. | 32 Kg. | ||

Number of specimen panels (15 x 30 mm.) | more than 120 | more than 180 | ||

Features | 1500 | 1500e | 3000 | 3000e |

Superior air-cooled Xenon Lamp: 1.500 hours lifetime | X | X | X | X |

Adjustment and control of irradiance level | X | X | X | X |

Display of current irradiance level |

| X |

| X |

Irradiance range: from 250 to 1.100 W/m² region (290 - 800 nm.) | X | X | X | X |

BST: control of temperature level, range: up to 100°C |

| X |

| X |

BST: display of current temperature value |

| X |

| X |

Timer for test time setting up to 999 hours | X | X | X | X |

Microprocessor control |

| X |

| X |

4 lines LCD for test parameters and program menu |

| X |

| X |

Bi-directional RS 232 interface for data output |

| X |

| X |

Free programming of 15 tests standards |

| X |

| X |

Special sensors calibration program |

| X |

| X |

Options and accessories | 1500 | 1500e | 3000 | 3000e |

Soda-lime glass UV filter, to simulate outdoor exposure | X | X | X | X |

Soda-lime glass UV filter, to simulate indoor exposure | X | X | X | X |

Soda-lime glass UV filter, to simulate outdoor exposure with Infra Red reflection coating | X | X | X | X |

Soda-lime glass UV filter, to simulate indoor exposure with Infra Red reflection coating | X | X | X | X |

SPECIAL tailored to specifications UV coated filters | X | X | X | X |

Flooding system for specimen |

| X |

| X |

Water cooled specimen table | X | X | X | X |

Test chamber humidity and temperature display |

| X |

| X |

Magnetic stirrer for liquid samples | X | X | X | X |

XEN 32 REPORT LEVEL |

| X |

| X |

XEN 32 MAINTENANCE LEVEL data transfer and calibration software using our radiometer |

| X |

| X |

Cooling unit, air refrigerator to reduce test temperature | X | X | X | X |

Radiometer and thermometer with sensors: | X | X | X | X |

Sensor 295-400 nm. wide band total UV | X | X | X | X |

Sensor 340 nm. narrow band | X | X | X | X |

Sensor 420 nm. narrow band | X | X | X | X |

Illuminance sensor up to 2 Mlux | X | X | X | X |

Black Standard Temperature sensor | X | X | X | X |