Display resolutions have continued to increase over the past few years. At the same time, LED chips for backlighting units, for example, have become smaller and smaller. The solder pastes used in serial production are increasingly reaching their limits in terms of mechanical properties and isotropic electrical conductivity.

DELO has specifically analyzed the feasibility of high-tech adhesives as a possible alternative to this established bonding method in a feasibility study.

Systematic testing shows that adhesives such as DELO MONOPOX AC268 prevent electrical short circuits in semiconductor components due to their intrinsic unidirectional conductivity, despite their reduced dimensions. In addition, it allows precision printing processes to be optimized, as larger stencil openings can be used. This significantly reduces pressure exerted on the substrate during doctoring and reduces the risk of damage.

Advantages at a glance:

- Intrinsic unidirectional conductivity

- Avoidance of electrical short circuits

- Optimization of precision printing processes

- Reduced risk of damage

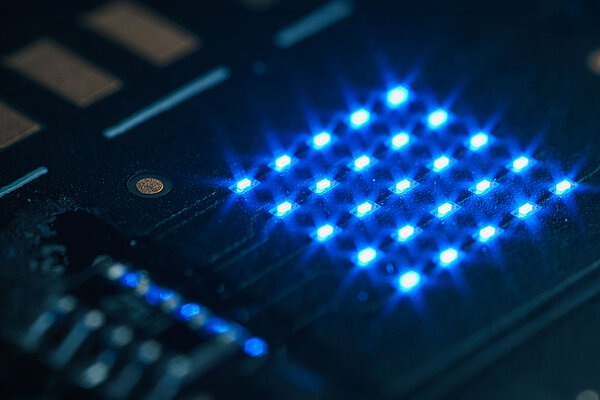

Our own test board for feasibility study

A test board was developed specifically for the feasibility study, which has sections for resistance measurements and daisy chain measurements. The suitability of the adhesive for dipping, stamping and time-pressure dispensing was positively demonstrated in this individual test series. During dipping, the contacts of the miniLED are dipped into a reservoir of DELO MONOPOX AC268 and then cured for 20 seconds at 180 °C using a thermode. Functional tests were then carried out, including energization (on-light tests) and recording of the current-voltage characteristics.

“These results prove that, indeed, adhesives are a suitable alternative to pick-and-place soldering for miniLED applications,” said Tim Cloppenborg, Senior Product Manager for LED at DELO. “Having a new, streamlined assembly process opens doors to increased production yields as well as the expedition of newer technologies, like microLEDs, which will enable fascinating new display applications within the next decade.”

Conclusion: Adhesives are key factors for the mass production of micro LEDs

For more information on our research results in the field of miniLED applications, please check out our whitepaper “The benefits of adhesives in mini & microLED display manufacturing”.

Source: DELO (https://www.delo-adhesives.com/us/press-and-news/delo-news/details/adhesives-for-miniled-and-microled-applications)

HUST Vietnam!