SIR13 – Insulation Degradation Measurement System for PCB Reliability Evaluation According to International Standards

10:54 - 05/02/2026

SIR13 (Insulation Degradation Measurement System) is a dedicated test system designed to evaluate surface insulation resistance (SIR) degradation on printed circuit boards (PCB, FPC). It is particularly effective for detecting electrochemical migration (ECM), a major failure mechanism that can lead

What is HALT and HASS testing?

Guide to choose Thermal shock test chamber

How to choose Temperature & Humidity test chamber?

Introduction to the SIR13 Insulation Degradation Measurement System

SIR13 is designed for high-speed, high-accuracy SIR measurement, making it suitable for both R&D laboratories and production quality control environments.

Key Technical Features

High-speed measurement down to 20 ms per channel

Supports up to 128 measurement channels at 250 V

Equipped with SMU (Source Measure Unit) boards for precise detection of leakage current and instantaneous ECM events

Supports per-pin bias and common bias measurement methods

Wide voltage range from 25 V up to 10 kV (depending on the measurement board)

19-inch rack-mount design, scalable and easy to integrate with environmental chambers

Compared with conventional SIR test systems, SIR13 enables simultaneous measurement of multiple samples, significantly reducing test time and minimizing the risk of missing short-term or intermittent short-circuit events.

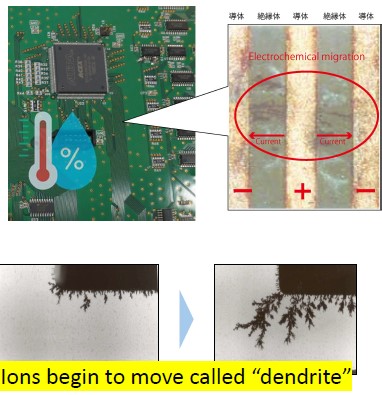

Principle of Insulation Degradation and ECM Measurement

By continuously measuring insulation resistance under high temperature and high humidity conditions, SIR13 enables early detection of leakage current and short-circuit formation, providing a reliable method for assessing the long-term reliability of PCB assemblies and electronic components.

This application note is prepared in accordance with widely recognized international standards, including:

IPC J-STD-004C – Flux qualification

IPC J-STD-001 – Requirements for soldered electrical and electronic assemblies

IPC-TM-650 (2.6.3.7) – Surface insulation resistance (SIR) and ECM test methods

Typical test conditions: 85°C / 85% RH, DC bias 50–100 V, test duration up to 168 hours

ECM Mechanism

Under the influence of DC electric field and moisture

Metal ions migrate from the anode to the cathode

Metallic dendrites are formed

Resulting in leakage current increase and short-circuit failure

SIR13 records data in real time and provides comprehensive analysis through Windows-based software, with support for temperature and humidity sensor integration to synchronize environmental conditions with electrical measurements.

Standard-Compliant Test Procedure Using SIR13

1. Sample Preparation

Use IPC-compliant test coupons

Comb-pattern electrode structures

Electrode spacing: 0.1 – 0.5 mm

Apply flux or soldering processes when evaluating manufacturing-related effects

2. SIR13 System Setup

Select the appropriate measurement board (e.g., 250 V per-pin 16-channel board)

Install up to 8 measurement boards in a single 19-inch rack

Configure control and analysis software

Interface with environmental chambers (e.g., ESPEC, ETAC)

3. SIR Testing Conditions

Environmental conditions:

85°C ±2°C / 85% RHDC bias voltage: 50–100 V (applied for at least 1 hour prior to measurement)

Measurement voltage: 100 V DC

Test duration: 24 – 168 hours

Acceptance criterion: SIR ≥ 10⁸ Ω in accordance with IPC J-STD-004C / IPC-TM-650

4. Data Analysis

Plot SIR versus time

Failure is identified when:

SIR drops below 10⁸ Ω

Short circuit occurs (<100 Ω)

Failure mechanisms are evaluated as ECM-related degradation

5. Reporting

Export test data in CSV format

Optional correlation with microscopic images of dendrite growth

Suitable for QA documentation, customer reports, and certification purposes

Benefits and Referenced Standards

Compliant with:

IPC-TM-650 for SIR and ECM testing

IEC 60068 for environmental testing

Enables early prediction of PCB and electronic component reliability

Ideal for applications in:

Automotive electronics

Industrial electronics

High-reliability electronic systems

Widely adopted in Japan, China, and Taiwan by PCB and PWB manufacturers

Early detection of insulation degradation helps reduce short-circuit risks, improving overall product safety and quality