Repair, maintenance of temperature chamber and thermal shock chamber in Dong Van II IP

The customer is a global LED manufacturing company. The products that the company is producing are smart products, with advanced technology, with high quality such as interior lighting, car lights, computer display lights, screens cars, cell phones, infrared lights ... and some other products.

Environmental testing is one of the key steps in a company's product quality control process to ensure the best quality is manufactured.

|  |

| Temperature chamber | Thermal shock test chamber |

Due to the process of working continuously for a long time without checking and maintenance, some temperature chambers and thermal shock chambers of the factory had incidents and failures.

On April 1, 2021, HUST Vietnam's engineers came down to directly inspect and determine the status of some temperature chambers and thermal shock chambers. Through preliminary inspection, the specific situation for each type has been identified: Temperature chamber: Controller is not powered on, an over-temperature alarm is broken ...; Thermal shock test chamber: Leaked gas in the pipeline, out of cold gas, the temperature did not reach the deep negative temperature (-40oC) ...

After the repair work, HUST Vietnam overcame some temperature chambers and thermal shock chambers and put them back to normal operation.

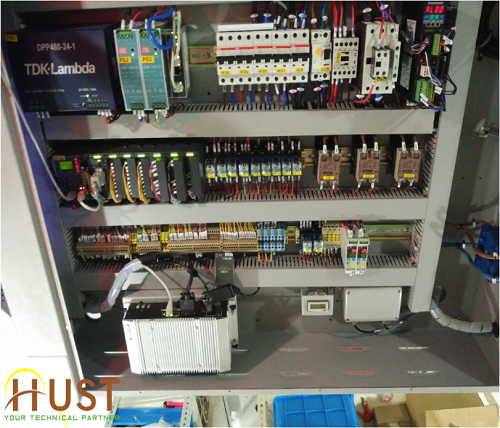

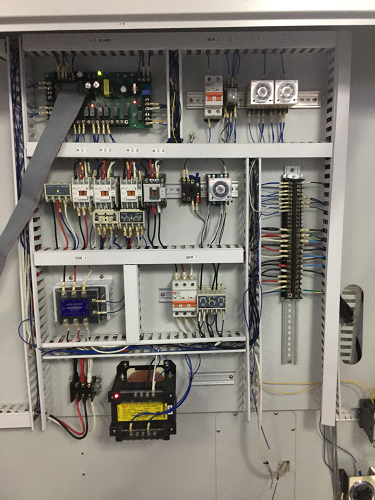

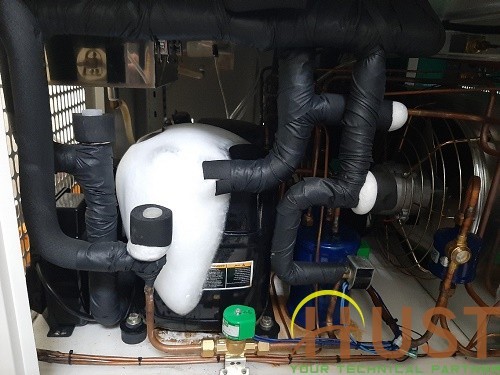

Some pictures during the inspection and repair process:

|  |

| Kiểm tra lại nguồn điện và bộ cảnh báo nhiệt | |

|  |

| Kiểm tra khí gas và kiểm tra rò rỉ | |

| |

| Nạp ga khí làm lạnh | |