Preparation method for Printed circuit board

10:35 - 13/07/2020

What is the right preparation method for Printed circuit board? Let study it with QATM' solutions. Cutting, Mounting, Grinding & Polishing machine

Steps | Recommended machines | Remarks | |||||

| CUTTING | ATM Brillant | - Cut-off wheel: corundum, resin bond | ||||

| MOUNTING | ATM Opal | - Cold mounting: KEM 20 | ||||

| GRINDING/ | Sample size | Pressure parameters and specimen size | ||||

25 | 30 | 40 | 50 | 60 | |||

-(5~10)N | -5N | 0 | +5N | +(5~10)N | |||

Step | Medium |

|

|

Rotate direction |

|

Time (min) | |

Planar grinding | SiC P180 | H2O | 250~300 | ►► Synchronous | 30 | Until plane (slightly before | |

| Grinding | SiC P800 | H2O | 250~300 | ►► Synchronous | 25 | 1:00 (until point of interest) |

| Grinding | SiC P1200 | H2O | 250~300 | ►► Synchronous | 25 | 1:00 (until point of interest) |

Polishing | Vải lụa GAMMA | Dung dịch Dia-Complete Poly, 3 µm | 120~150 | ►► Synchronous | 30 | 3:00 | |

Final polishing | Vải tổng hợp OMEGA | Eposal, | 120~150 | ◄ ► Counter | 25 | 2:00 | |

BEGINNERS GUIDE :

Step | Detailed instructions | |

| CUTTING | - Use suitable cut-off wheels for ferrous material (e.g. ATM FS-E wheels) |

| | MOUNTING | - Use mounting material for almost gap-free mounting |

| | GRINDING | - Start grinding with SiC-paper/foil P180 |

| | POLISHING | - Rinse the polishing discs with water and spin dry after use - Do not stack discs with different diamond sizes - Clean samples, holders and hands under running water before each polishing step - Use ethanol and blow dryer to avoid water stains - Check after each step under the microscope if polishing marks are of equal size and randomly oriented - Use the consumables only for printed circuit boards and not for other materials - Rinse the cap of the Eposal bottle after use, put cap back on - Use cosmetic tissues to clean possible traces of Eposal after the last polishing step |

SAMPLE MICROGRAPHS:

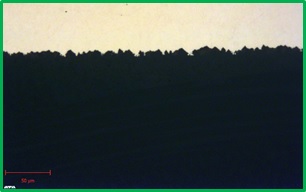

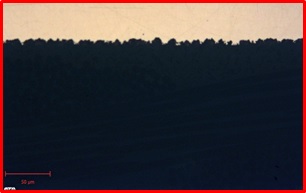

OK Sample polished | NOK Sample polished |

- No traces of scratches

| • Sparse scratches from 0.06 µm Eposal after |

|  |

20x micrograph of printed circuit board (non assembled) after OMEGA polishing | |

TÀI LIỆU THAM KHẢO: