Automotive headlight manufacturers face two key challenges: miniaturization and increased functionality. Modern headlights are narrower but must also be more powerful. Conventional joining methods such as screwed-on connections are reaching their limits. Demand for innovative adhesive solutions, meanwhile, is growing. However, they must meet a slew of strict requirements: They must be stress-equalizing, low outgassing, extremely temperature-resistant, and yet remain highly transparent.

DELO has developed DELO PHOTOBOND OB4210, a groundbreaking active alignment adhesive. It is perfectly adapted to the requirements of modern headlight designs and offers excellent yellowing stability, even at high temperatures. It enables fast UV curing and is compatible with a wide range of substrate materials.

An adhesive that sets the standard

With DELO PHOTOBOND OB4210, we have created an adhesive that meets the increasing automotive lighting requirements. Our solution:

- High transparency: Virtually indistinguishable from the lens material.

- Improved yellowing stability: Remains stable after a typical storage time of 500 hours at +140 °C.

- Versatile adhesion: Suitable for various materials within the headlight.

- Fast UV curing: Enables process advantages in production.

Advantages:

- Wide elasticity ranges: Ideal for tension equalization.

- Curing in seconds: Shorter cycle times for higher throughput.

- High temperature resistance: Resistant to temperatures between -40 °C and +140 °C.

- High compressive shear strength: 35 MPa on polycarbonate.

- Good flowability on larger surfaces: Thanks to a low viscosity of 3,000 mPa-s.

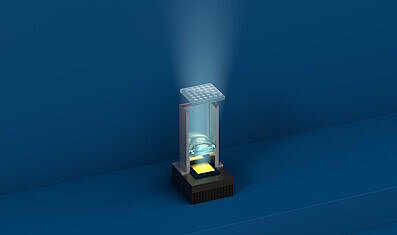

Schematic representation of bonding areas for the fixation and alignment of optics in a microlens array headlamp module, adhesive colored magenta for illustration purposes (Image: DELO)

More than just an adhesive

The DELO PHOTOBOND OB4210 acrylic adhesive intrigues with its versatile application possibilities. Due to its almost immediate UV curing, it is suitable for high-end applications such as active alignment in lens systems, optics in matrix LEDs, microlens arrays or digital light processing spotlight systems.

"With DELO PHOTOBOND OB4210, we are expanding our portfolio with an extremely yellowing-resistant product with high strength. These properties are essential for optically demanding applications and ideal for modern headlight designs," says Christoph Appel, Product Manager LED Automotive at DELO.

Conclusion

With DELO PHOTOBOND OB4210, we offer an adhesive solution that meets the increasing automotive industry requirements. Thanks to its excellent properties, it is ideal for the increasing miniaturization and functionality of automotive headlights.

Call to Action Area: Would you like to learn more about DELO PHOTOBOND OB4210 and our other adhesive solutions? Visit us at the DVN Conference on December 4th and 5th in Shanghai and experience our innovations live!

(Source: DELO - https://www.delo-adhesives.com/us/press-and-news/delo-news/details/transparent-and-high-performance-headlight-adhesive)

HUST Vietnam!