Maintenance and Repair of Salt spray tester - Increase Efficiency & Durability

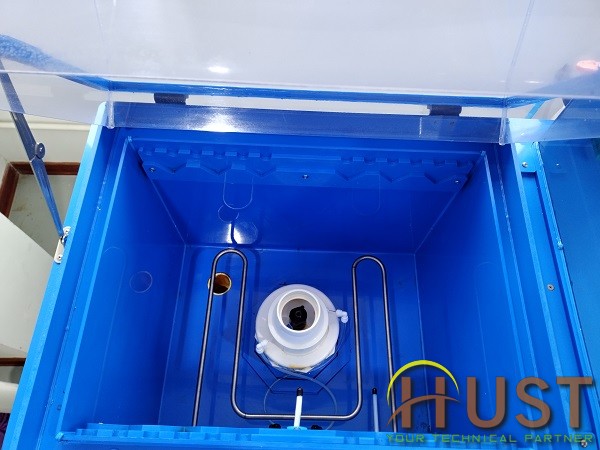

In mid-February 2025, HUST Vietnam performed maintenance and repair of a salt spray machine for a customer in Bac Giang.

Before performing maintenance, the customer's salt spray machine had some problems as follows:

- The spray chamber temperature did not reach the set value, affecting the accuracy of the experimental results.

- The machine always sprayed salt even without an activation command, causing waste of solution and reducing work efficiency.

- The salt vapor was not discharged when sampling inside the laboratory chamber was needed, causing inconvenience to the operator.

HUST Vietnam inspected, determined the cause of the problem and performed repair steps as well as replaced damaged components. We also performed a general maintenance process for the machine.

After replacing components, maintaining and checking the operation, the salt spray machine operated stably:

- The spray chamber temperature reached the correct set value, ensuring the accuracy of the experiments.

- The salt spray system only operates on command, no longer continuously spraying causing waste.

The salt vapor discharge function works well, supporting the correct and safe sampling process.

Benefits of regular salt spray machine maintenance:

- Increase equipment life, reduce the risk of damage.

- Ensure accuracy in salt spray testing.

- Save long-term maintenance and repair costs.

With the above improvements, the equipment has returned to operating status according to the manufacturer's standards, helping to optimize efficiency and accuracy in operation.

Contact us now for advice on salt spray machine maintenance.