Faster than ever before

The Qpress 40 is a robust hot mounting press for exceptionally fast mounting processes. Thanks to its powerful heating/cooling technology and speed-optimized temperature control, the mounting time is significantly reduced. The robust bayonet closure, optional simple one-button operation, and clear parameter display on the 7" industrial touchscreen ensure convenient and intuitive use. The connectable, patented extraction system sets new standards in occupational safety for the user.

Product Advantages

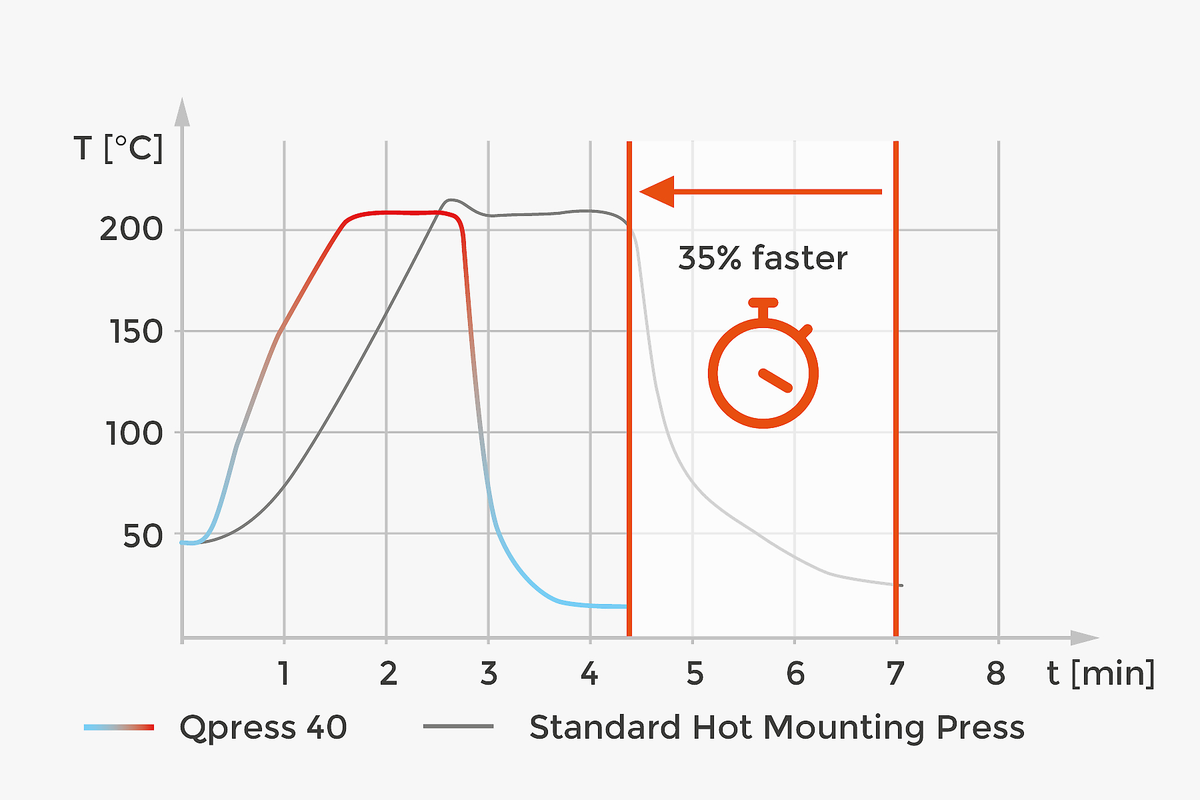

- Short mounting times (up to 35% time savings)

- Robust bayonet quick-release closure

- 7" touch display with innovative control software and optional one-button operation

- Dust Guard: extraction of granule dust during filling (patented)

- Compact and high-quality design with powder-coated metal housing

- High sample throughput possible due to double mounting

|  |  |

Speed-optimized heating and cooling technologyShorter mounting times are achieved by:

| Simple one-button operationThe highest possible operating safety is achieved with the butler function. In just a few steps, the entire mounting process can be controlled by pressing the multifunction button. In addition, the PLUS software has a method database with pre-installed, consumable-specific mounting recipes and allows the storage of more than 128 user-defined mounting methods. This ensures the fastest possible operation with maximum process reliability. | Extraction of fine dustThe patented and optional integrable suction device (Dust Guard) protects the user from inhaling dust that can escape when the mounting resin is filled into the mould. This significantly enhances health protection in the workplace. In the PLUS software version, the extraction system is automatically controlled by the software. |

Functional Principle

The new design of the Qpress 40 ensures the shortest possible heating and cooling times. The heating elements quickly melt the mounting resin thanks to optimized heat transfer and temperature control in the mould. During this process, the granules are compressed to the preset mould pressure. Once the set temperature is reached, the press mould is cooled as quickly as possible after a short holding time, allowing the hardened sample to be removed for further preparation. This not only saves time but also reduces energy requirements.

Technical Data:

| Mould Ø (metric) | Ø 25 mm, Ø 30 mm, Ø 40 mm |

| Mould Ø (inch) | Ø 1", Ø 1 1/4", Ø 1 1/2" |

| Max. pressure in mould cylinder Ø 40 mm / Ø 1.5" | 250 bar |

| Max. pressure in mould cylinder < Ø 40 mm | 350 bar |

| Adjustable temperature | 20 - 200°C |

| Drive power (hydraulics) | 0.36 kW |

| Heating capacity | 1.6 kW |

| Connected load | 2.0 kW |

| Heating time (adjustable) | 0 - 30 min; in 15 s steps |

| Cooling time (adjustable) | 0 - 30 min; in 15 s steps |

| Dimensions (WxHxD) | ~ 365 x 433 x 538mm |

| Weight | ~ 41 kg |