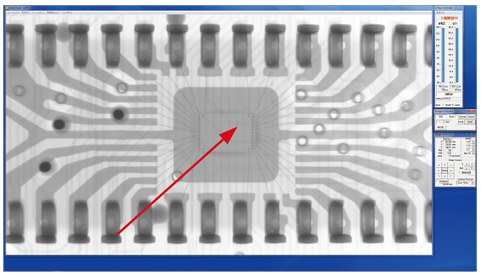

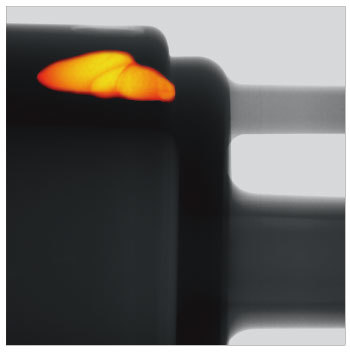

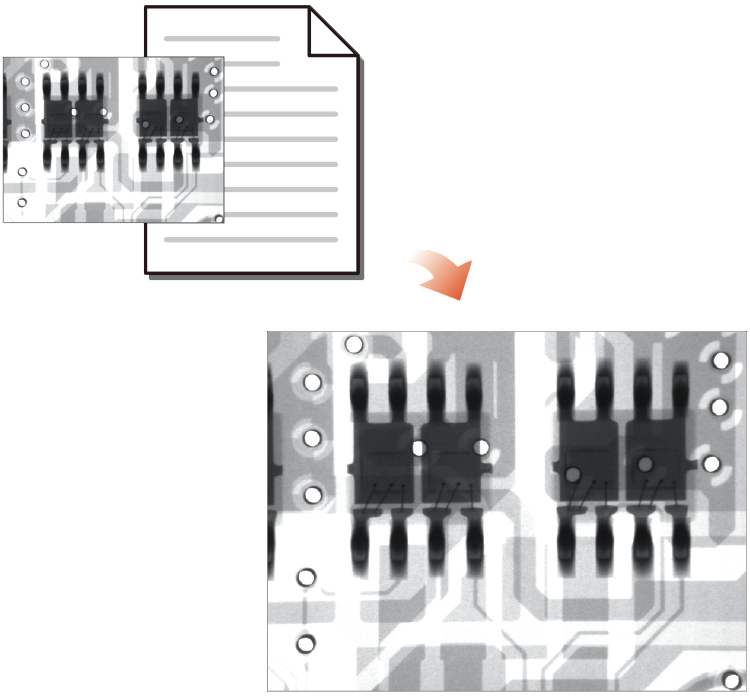

Clearly penetrating images come with 130 kV high power X-ray tube and high resolution X-ray camera.

The series has prominently high penetration and power up to 40 W, so you will readily find out hidden defects that had never been seen before. High performance X-ray CT inspection system µRay8700/8760 Series will introduce new penetrating observation technology.

Using 130 kV high power X-ray tube and high resolution X-ray camera designed for clear penetrating images, the series provides a higher-ranking penetrating observation system. We developed our exclusive noise reduction technology as well as the smallest focal spot size of 5µm with 4 W output.

Especially, incredible low noise and high contrast are achieved by the micro-focus X-ray tube. In addition to such superior images, the exclusive software having many effective functions along with superior operability makes µRay8700/8760 series exceptionally high quality system in non-destructive inspection.

Features

- High power X-ray up to 40W

- Using lateral irradiation for simple fixation

- Easy operation with attached software

- Possible to observe the entire a large sample

- Corresponding to CT Unit (option)

Models

| Model | X-ray generator | Stage | |

|---|---|---|---|

| Tube voltage | Output power | Sample size available for placing | |

| µRay8700-LF | 40 kV to 130 kV | at small focal spot: 8 W MAX (177 µA MAX) at large focal spot: 40 W MAX (300 µA MAX) | φ 200 x 340 (H) mm The field of view ranges is unchanged. |

| µRay8760-LF | φ 200 x 700 (H) mm The field of view ranges is unchanged. | ||

Functions

Lateral irradiation allows for simple fixation of work

Also, X axis (left and right), Y axis (front and back), Z axis (up and down) and rotary axis (turning) are included to support easy observation.

A round work can be easily observed by placing it on the stage and turning it 360 degrees. The stage can be moved to the left/right, front/back, and up/down, allowing for easy operation.

Using a large space stage 100 mm in diameter together with the sample fixing platform, the series offers different height settings at work as you need.

(As to sample fixing, there are variations according to works. Please contact our sales representatives for details.)

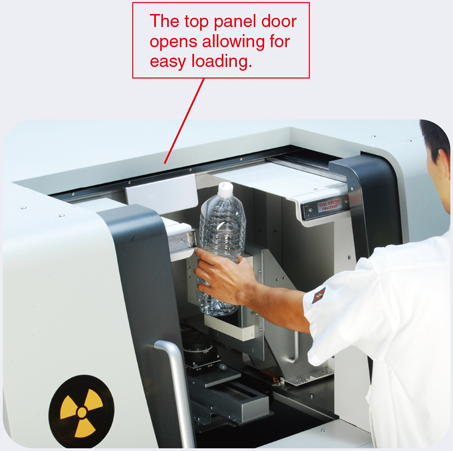

As the top panel door opens*1, a long or heavy work (10 kg)*2 can easily be loaded on the stage.

- The door of the ceiling is not attached in µRay8760

- The durable supporting weighting 10 kg is optional.

It is difficult to work with only a front door.

Software

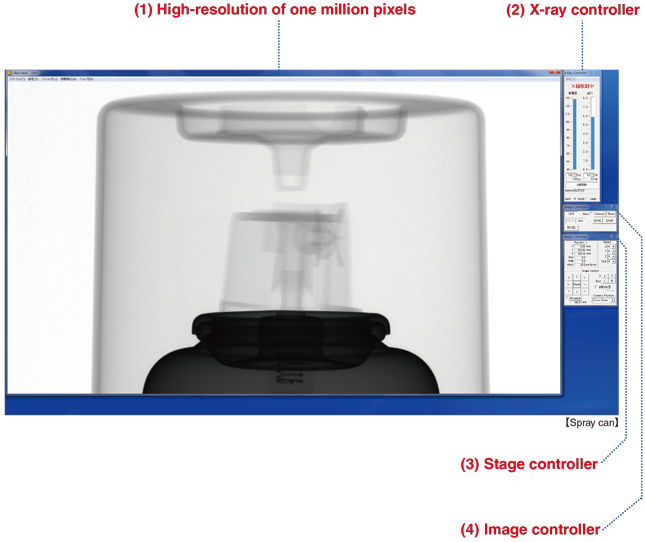

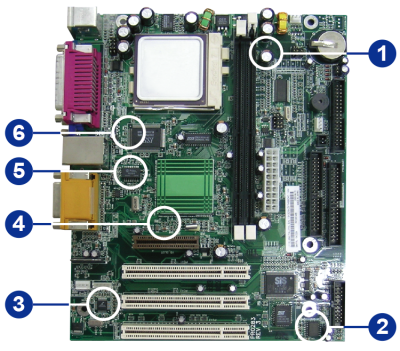

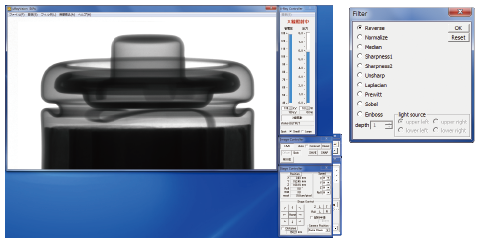

µRay®Vision

Simple operation allows for use of necessary functions by "anyone" "in no time".

The accompanying dedicated software, "µRay®Vision", not only allows for stage controland simple X-ray operation but also features a variety of image processing and measurement functions.

- (1) High-resolution of one million pixels

- A transparent image is displayed in real time.

- (2) X-ray controller

- Controls X-ray’s ON/Off, tube voltage, and tube current.

- (3) Stage controller

- Stage is operated by mouse.

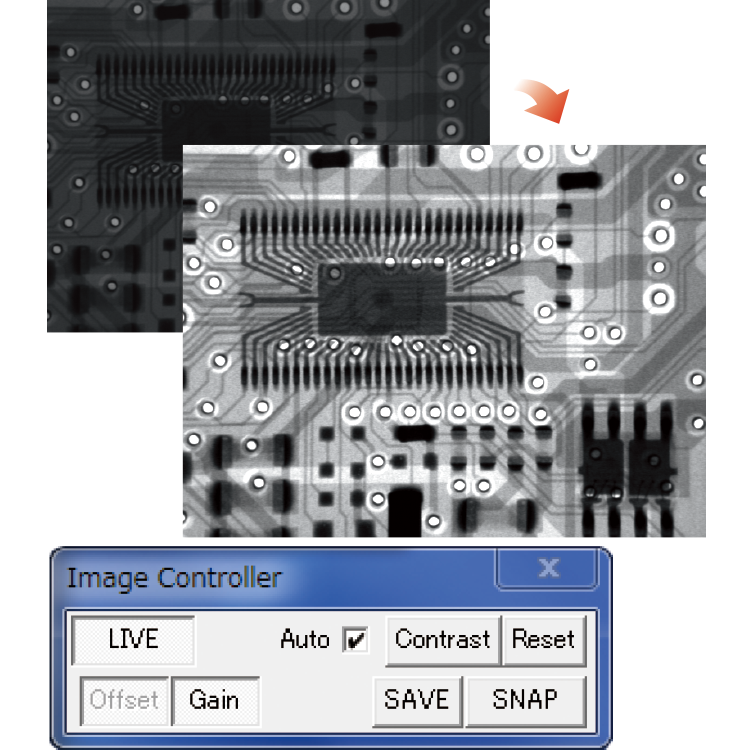

- (4) Image controller

- Configures video filter, display range setting, and other loading methods.

Chap. 1 Simple observation and analysis

Easy observation and analysis at the micro/macro level and in various directions

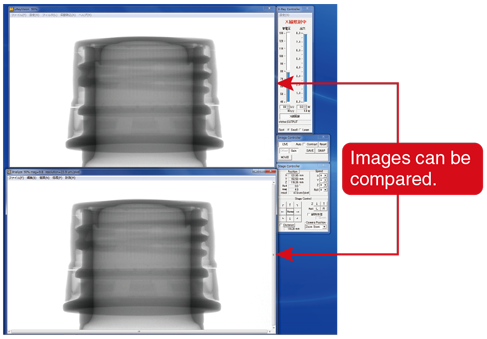

With the reduced display function, you can easily make comparative observations.

By switching from the high-resolution display to the reduced display, you can perform observation/analysis of the sample by comparing it with previously saved images.

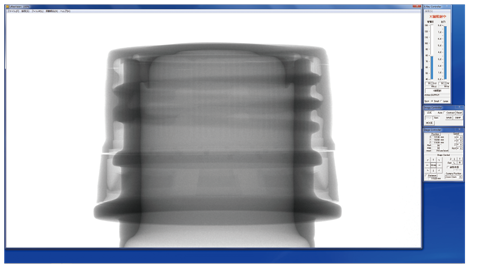

High-resolution display

Reduced display

With a move and a click, details can easily be observed.

This function is helpful for when you "want to observe the details of a sample while maintaining high resolution".

Because the stage moves to the part that's clicked, no details will be missed.

By gradually moving the stage, the whole area can be observed without missing anything.

The screen centers on the point clicked.

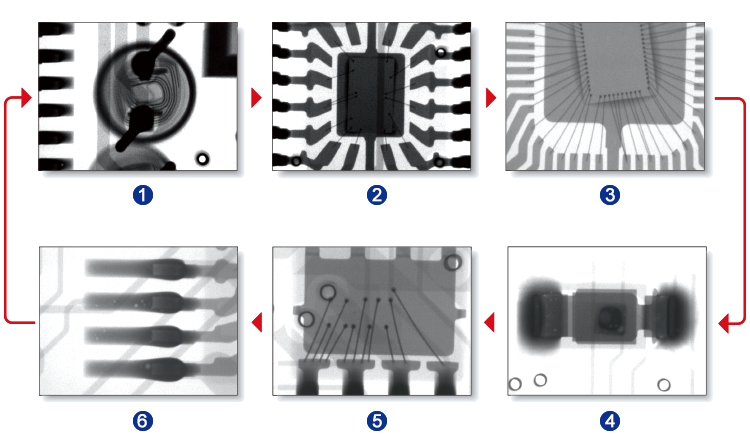

Chap. 2 Simplifying lot inspection and all quantity inspection

Easy and fast operation for all quantity inspection

TEACHING function makes it easier to inspect the certain sample repeatedly in the specific part.

This function improves inspection efficiency by automatically moving the stage to pre-registered points. Once the positional data has been stored, you can display images of exactly the same points on multiple specimens with the same shape. Also, because settings such as the X-ray output rate, the magnification rate, and the stop time can be configured individually for each point, any type of specimen can be handled.

Chap. 3 Quick response to complicated judgments

Betterment of pass/fall judgment

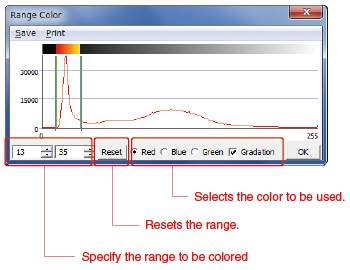

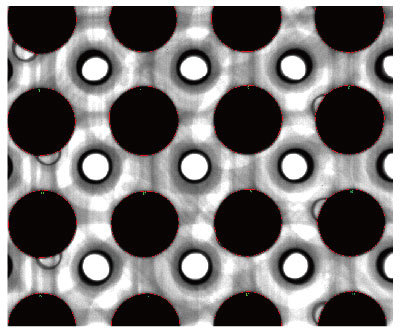

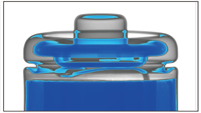

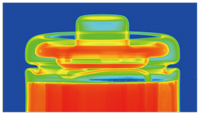

COLORING function makes it easier to find defects

This function detects the gray level of points where foreign matter or faults are identified in a defective specimen. It then adds color to all points that have the same gray level. Since color is added only to areas with a gray level that indicates a defect, this function allows you to assign a pass/fail more easily.

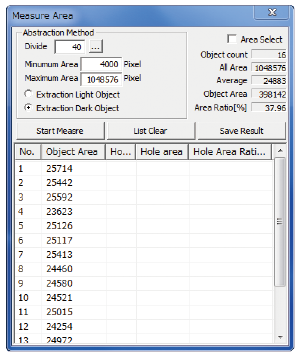

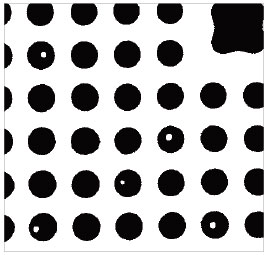

AREA CALCULATION function makes it easier to inspect samples using the areas.

This function helps you to identify differences in size when examining rows of the same object or of different objects with the same shape and to judge the results of void fraction measurements for BGAs. The measurement results are quantified and then used to measure the surface areas, number of holes, hole areas, and area ratio.

Chap. 4 Easy operation for image processing and analysis

With the exclusive software as standard, the advanced image processing and analysis are available in simple operations

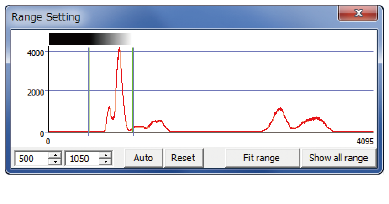

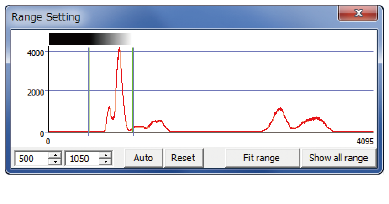

Display Range

Allows you to set an arbitrary gray level based on an image's histogram and then enhance the contrast manually.

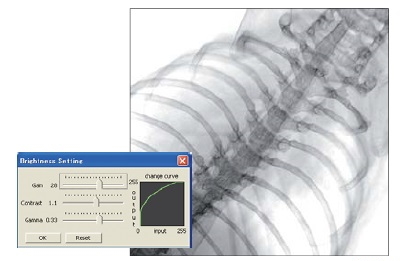

Brightness control

Individually controlling the gain, contrast, and gamma values allows for flexible change of the brightness value of images.

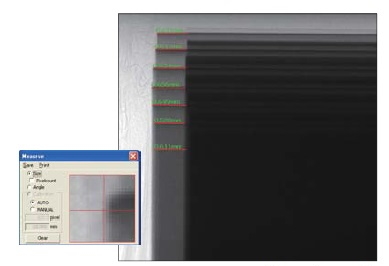

Size measurement

By drawing the measurement lines on the image, the dimensions within the image can be measured.

Threshold

Allows you to set all values above the threshold to white and all values below it to black.

Filters

The µRay series provides more than ten different types of filters and image processing functions that enable more detailed image analysis. Applying a filter to a moving image enables you to perform real-time image analysis.

-

3D

-

Sobel

-

Coloring

-

Emboss

-

Gradation reverse

-

Pseudo-coloring

No specialist knowledge or qualifications required

leading to user-friendly and safety for all

Reliability Latest ACC function

Just a single click required even for the first specimen

The automatic contrast control (ACC) function selects the most suitable contrast setting for the image. No matter who is using the system, a high-definition X-ray image can be readily obtained.

Reliability Imaging conditions replication function

Leveraging previously used conditions to simplify the process

By loading the imaging conditions file for a previously captured image, you can capture new images under the exact same conditions. This eliminates the risk of mistakes being made, regardless of who is using the system.

Reliability Automatic aging function

Maintenance free

The system memorizes the time and date of use. The aging time is automatically selected based on how many hours have passed since that day to ensure optimum aging.

[If the aging function is not performed properly, the service life of the X-ray tube could be shortened.]

Safety Interlock function

The system stops emitting X-rays immediately if the door is opened.

Safety Auto-off function

In case you forget to turn off the X-ray source, the system automatically stops X-ray irradiation after a set time has elapsed. The maximum setting is 30 minutes.

Safety Emergency stop button

This button is to be used only in an emergency. It stops X-ray irradiation and stage movement immediately.

Options

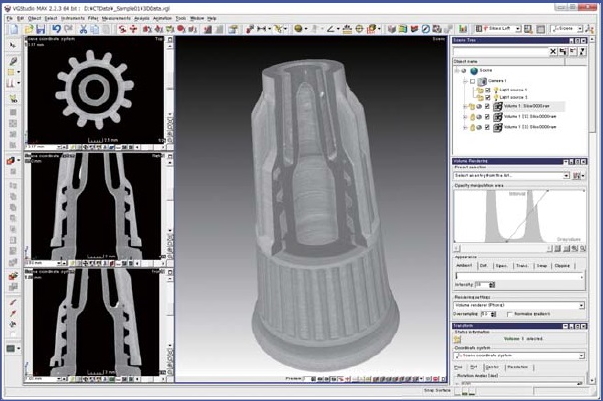

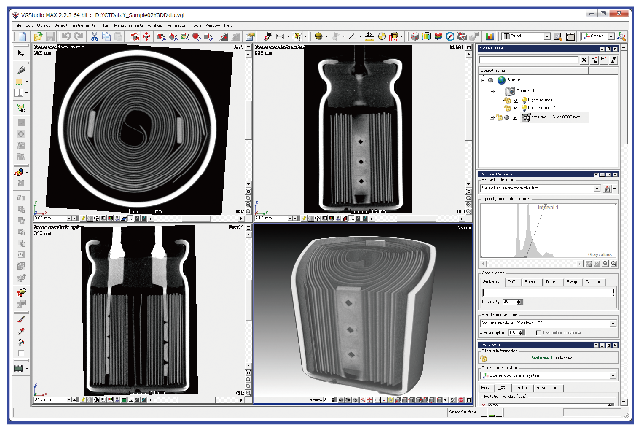

CT Unit: 2D/3D analysis software (-LCT option)

A fluoroscope can only capture projection images, but a CT Unit can capture 3D images. A CT Unit can also capture tomographic images of the specified surface of a 3D image.

Display software

The display software enables you to obtain clear 3D images within 15 minutes. The 3D position displays make it easy to perform high-accuracy analysis. The software provides all of the functions needed for CT and image analysis.

Tomographic images can be observed from three directions.

CT specifications [-LCTN, -LCTM, and -LCTX options]

CT processing software

| Reconfiguration matrix | 2304 x 2304 x 1300 |

|---|---|

| Scan mode | Normal scan, Half scan, Offset scan |

| Number of slices | 320, 640, 96, 1300 |

| Number of views | 150, 300, 600, 1,000, 3,000, 5,000 |

Image processing

| 3D display | MPR display, Volume rendering display, MIP display |

|---|---|

| 3D analysis | Volume measurement, Filter, Movie output, CAD data output, Image file output |

Wide-field and high-resolution digital FPD option (-LFG3/-LF6)

The optional wider field and higher resolution imaging units are selected over the standard equipment. The wider field 3-million-pixel digital FPD provides 4.2 times the standard imaging range to take an image at only one time. In addition, using the 6-million-pixel digital FPD, you can achieve more definitive observations with higher resolution as well as wider field.

| Standard or option | Standard (3-million-pixels FPD) | 3-million-pixels option (with wider field) | 6-million-pixels option (with higher resolution and wider field) |

|---|---|---|---|

| Options | - | µRay8700-LFG3 µRay8760-LFG3 | µRay8700-LF6 µRay8760-LF6 |

| Visual field size | 64 x 114 mm | 153 x 204 mm | 114 x 146 mm |

| Effective pixels | 3 million pixels | 1548 x 2064 pixels | 2304 x 2940 pixels |

| Density resolution | 14 bit | 14 bit | 14 bit |

| Monitor Size | 27 inches | 27 inches | 27 inches |

| Geometrical magnification ratio (times) | Max 9.5 | Max 9.5 | Max 9.5 |

| Min 1.4 | Min 1.4 | Min 1.4 | |

| Monitor magnification ratio | Max 44.8 | Max 22.4 | Max 29.7 |

| Min 6.7 | Min 3.2 | Min 4.4 | |

| Inspection visual field (mm) | Max 6.8 x 12.0 | Max 16.2 x 21.6 | Max 12.1 x 15.4 |

| Min 45.8 x 81.3 | Min 109.4 x 145.9 | Min 81.6 x 104.1 |