DELO MONOPOX ACxxxx – ANISOTROPIC CONDUCTIVE ADHESIVES

Introduce:

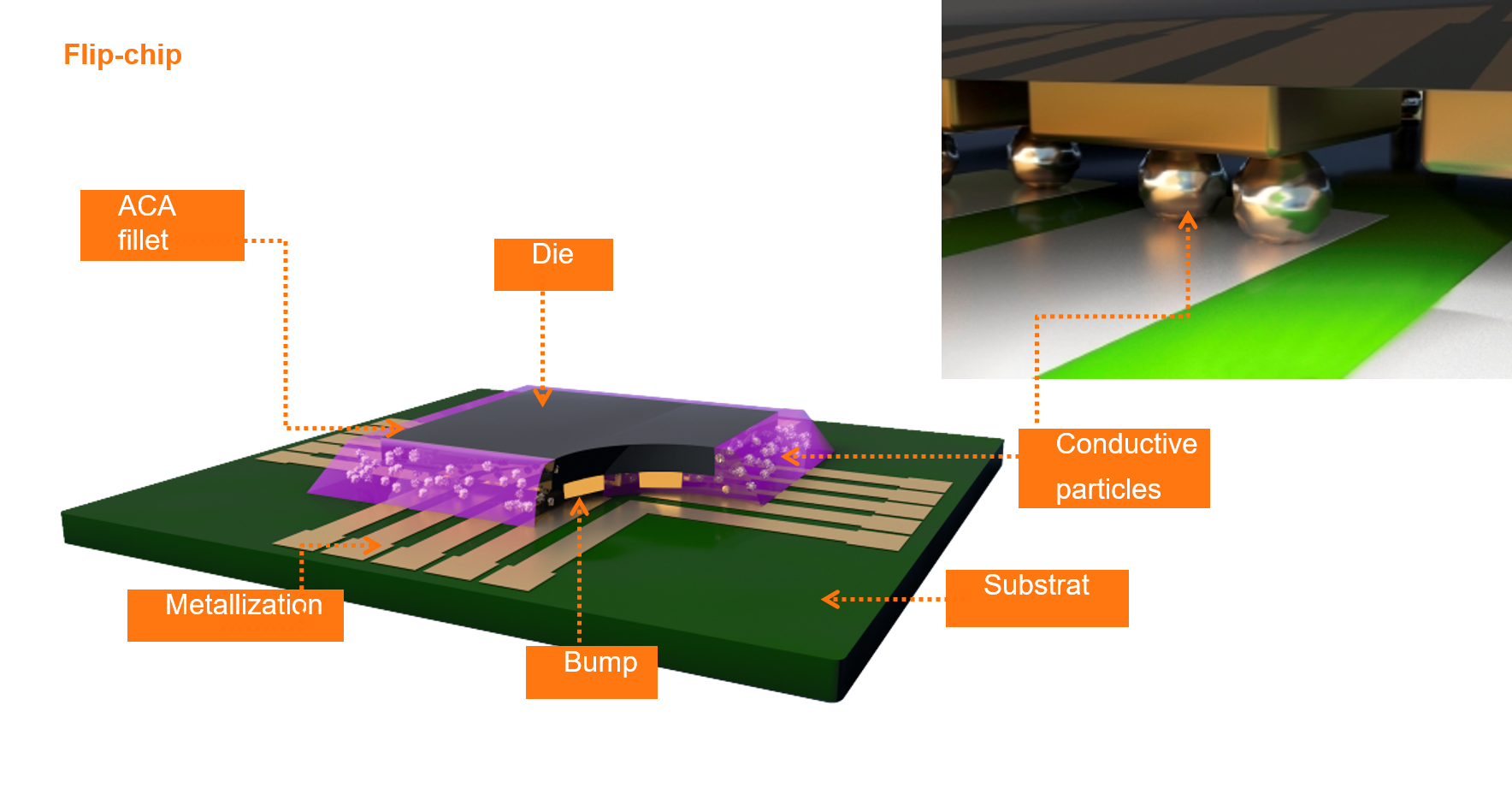

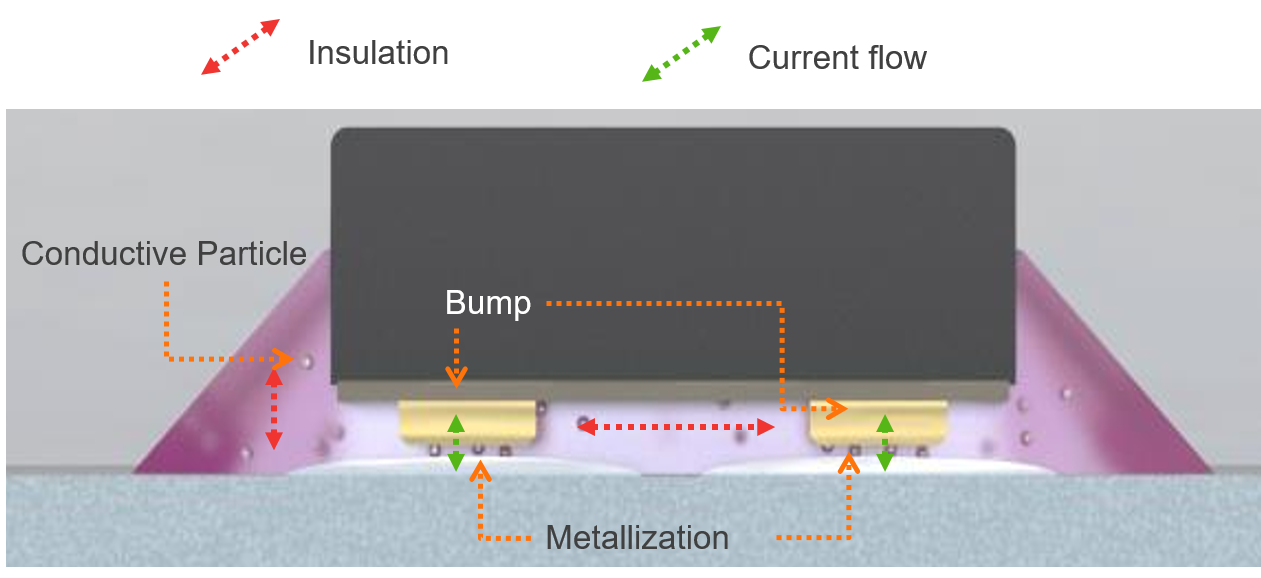

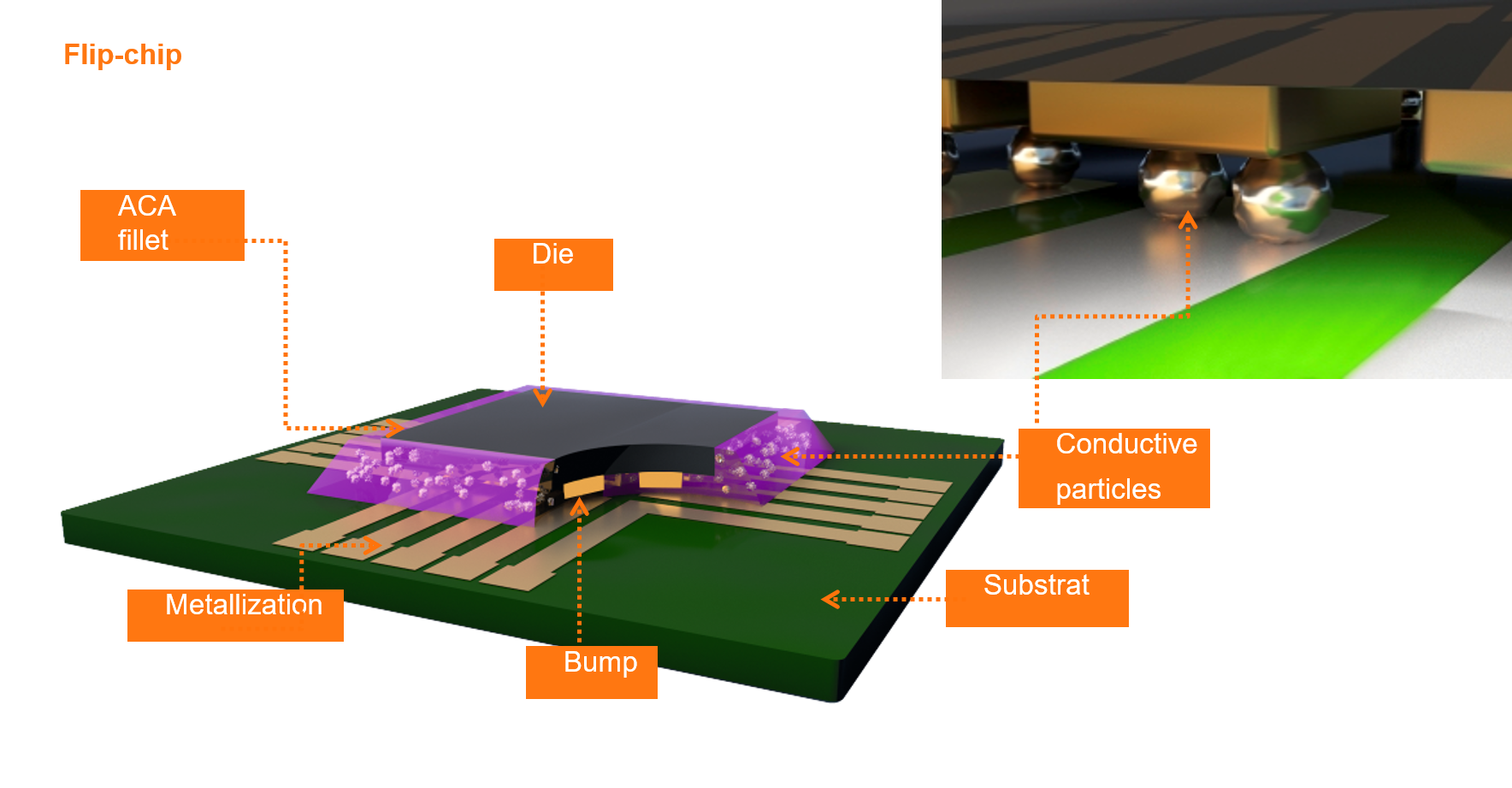

DELO MONOPOX ACxxxx adhesive group (AC = Anisotropic Conductive) is a 1-component adhesive, derived from modified epoxy resin, cured at high temperatures, heat resistant, mechanically durable, and anisotropic electrical conductivity thanks to metallic Nickel particles of the same size are mixed into the glue.

Outstanding features:

The glue is filled with micrometer-sized metal particles that conduct electricity in a certain direction (anisotropic) to meet the adhesion and conductivity requirements in the electronics industry.

Featured applications:

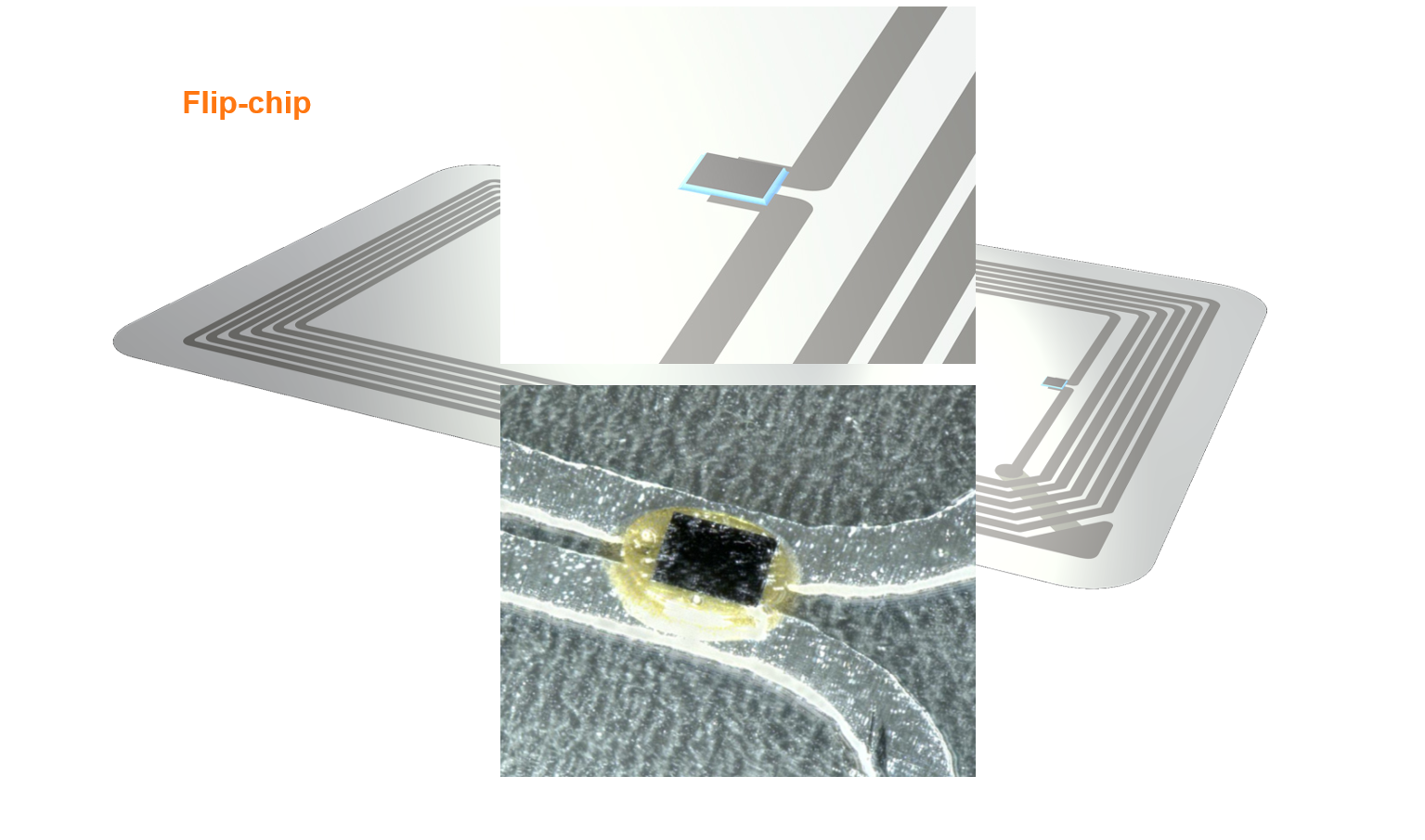

- Specialized adhesive for circuit pins that need to be soldered to the PCB printed circuit board.

- The glue cures in just a few seconds with a high-temperature welding tip (thermode).

Technology parameters:

Parameter | AC265 | AC6530 | AC6545 | AC2264 | ||||

Components | 1-component from modified epoxy | |||||||

Color | grey, opaque | Black, opaque | grey, opaque | grey, opaque | grey, opaque | grey, opaque | Black, opaque | |

Filler | Nikel, d50 = 2.5μm | Nikel, d50 = 5μm | ||||||

Application | Adhesive semiconductor chips in plastic cards | |||||||

Usage temperature | -40 ~ + 150 oC | |||||||

Processing time | 14 days | 72h | 14 days | 72h | 72h | 72h | 72h | |

Storage time | 06 months at -18 oC | |||||||

Curing time | Use heat-soldering head (thermode) | 8s at 180 oC | 8s at 170 oC | 8s at 180 oC |

| 8s at 180 oC | 8s at 180 oC | 9s at 150 oC |

6s at 200 oC | 6s at 190 oC |

| 1s at 230 oC | 1s at 230 oC | 1s at 230 oC |

| ||

Use a convection oven |

| 15 min |

| 10 min |

|

| 20 min at 60 oC | |

Density (g/cm 3 ) | 1.3 | 1.51 | 1.48 | 1.85 | 2.41 | 1.76 | 1.77 | |

Viscosity (mPa.s) | 37000 | 28000 | 45000 | 20000 | 42500 | 95000 | 60000 | |

Die shear (Au/Si) |

| 43 N |

| 21 N |

|

| 56 N | |

Shear compressive strength (MPa) |

| 47 |

| 37 |

|

| 18 | |

Tensile strength (DIN ISO 527) (MPa) | 50 |

|

|

|

|

|

| |

Elongation at tear | 1.7% | 1.7% |

|

|

|

|

| |

Young's stress (MPa) | 3300 | 3700 | 2400 |

|

| 4000 |

| |

Shore hardness |

| D 83 | D 83 |

|

| D 88 |

| |

Glass transition heat (oC) | 135 | 153 | 149 | 161 | 165 | 143 |

| |

Thermal expansion coefficient | 61 ppm/K (30~100 oC) | 60 ppm/K (28~110 oC) | 52 ppm/K (-40~60 oC) | 71 ppm/K (31~80 oC) | 54 ppm/K (31~80 oC) | 52 ppm/K (-35 ~ 40 oC) |

| |

Shrinkage (%vol) |

| 1.3%vol. | 1.5%vol. |

| 2 %vol. | 3 %vol. |

| |

Water absorption | 0.4 %wt. | 0.3 %wt. | 0.27 %wt. | 0.2 %wt. | 0.2 %wt. | 0.2 %wt. |

| |

Special features |

| Suitable for applying glue using a non-contact spray valve. Compatible with many types of materials. |

| The production process is quick thanks to the fast-curing glue |

|

| Cures at low temperature | |

Contact us for more value consultants.

HUST Vietnam is proud to be the exclusive distributor of adhesive products, dispensing - curing technology, and technology transfer from DELO in Vietnam!