This adhesive is DELO’s first dual-curing high-temperature structural adhesive. It is designed for use in multiple processes, including magnet bonding and magnet stacking, both of which can be found in electric motor manufacturing. It is the first heat-resistant adhesive capable of light fixation. Having this second means of curing helps electric motor manufacturers quicken assembly processes, and optimize efficiency in their production.

DUALBOND HT2990 is fast curing as well, achieving light fixation in 5–10 seconds. In magnet bonding, while heat is the standard method of curing, supplementing it with light fixation creates an already-cured outer layer that helps keep everything in place. The adhesive does not seep outside or onto the motor laminations. In magnet stacking, supplementing heat curing with light fixation lets you forego having to keep magnets under a jig in the oven to reach the desired bond line thickness.

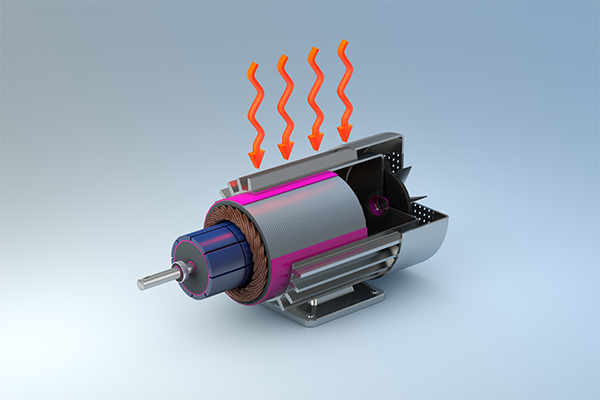

Final curing with heat takes 30 minutes at 150 °C or 60 minutes at 130 °C. If exposure to heat occurs later in electric motor assembly, for example via heat shrinkage, there is a possibility for the heat curing step to be skipped. Induction curing can be another alternative to oven curing as well.

At room temperature, DUALBOND HT2990 can achieve a compression shear strength of up to 70 MPa on steel. This compares to 45 MPa achieved by standard high-performance heat-curing epoxies. It also has a high glass transition temperature of 165 °C. In heat as extreme as 180 °C, it still exhibited a tensile shear strength of 7 MPa on aluminum. While this figure may seem small, it’s equivalent to 70 kg/cm² of force, a very secure bond.

To learn more about DELO DUALBOND HT2990 and its applications, DELO is offering a free webinar, “High-Temperature Adhesives", on July 19, 2023, at 11:00 a.m. CET. Industry experts will provide insight into electric motor applications and how high-temperature adhesives, like DELO DUALBOND HT2990, can help optimize these processes, with some being able to withstand up to 20,000 hours of exposure to extreme heat.

Watch more processing video: https://youtu.be/F2trVxQza7c

HUST Vietnam JSC - authority distributor of DELO Adhesives in Vietnam!