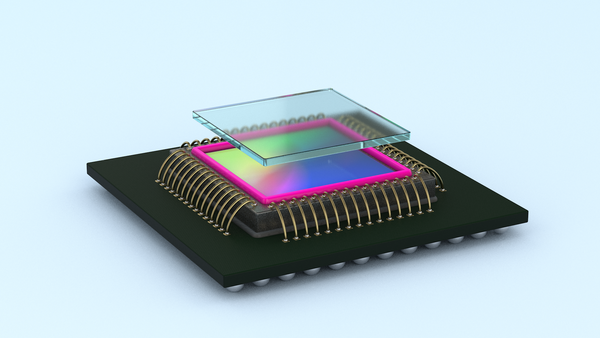

DELO DUALBOND - Airtight Sealing of Automotive Image Sensors

Common Challenges

Airtight packaging for semiconductor applications, particularly for automotive sensors, presents a formidable challenge. Ensuring that image sensors maintain their airtight seal while compensating for internal pressure variations is paramount. These pressure changes occur due to temperature fluctuations, with air volumes expanding or contracting, thereby exerting stress on the adhesive bonds. Typical defect patterns are cracks, delaminations, or tilt, in which the cover glass becomes misaligned. All error patterns are judged as defects and must be avoided.

Furthermore, issues such as outgassing and bleeding pose a contamination risk that can compromise sensor performance through corrosion or image quality degradation. Hence, a novel glass lid adhesive solution is crucial to address and eliminate these defect patterns.

Key features of tested adhesives DELO DUALBOND BS3770 and DELO DUALBOND EG6290:

› Enhanced reliability of safety-critical systems: Long-term hermetic sealing of image sensors in ADAS — even in complex package geometries.

› Reliable sealing: Compensates pressure changes from heat, humidity, or reflow processes, preventing defects like delamination or pop-ups

› Precise application: Needle dispensing with narrow, high bondlines

› Dual-curing option: UV light fixation within seconds, final thermal cure

› Designed for strict industry standards: Meets AEC-Q100 automotive qualification

For more information, click on this link:

https://www.delo-adhesives.com/service/whitepaper/airtight-sealing-of-automotive-image-sensors/