Features & Specification

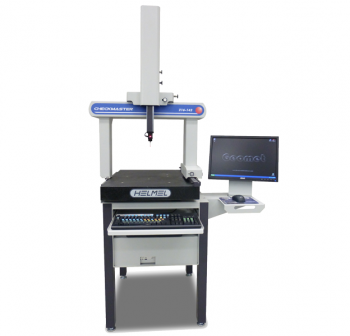

The MICROSTAR 320-185 Coordinate Measuring Machine has been developed to take advantage of the High Performance PH20 5-AXIS Probe. The system is an evolution of Helmel's time tested and thoroughly proven Microstar CMM Series of all mechanical bearing machines with intrinsic mechanical accuracy. It features the PH20 Infinite Positioning probe concept that combines true 5-axis motion capabilities with autonomous head-tap measuring, allowing access to tight spaces and precise measurement of many features with the head only while the CMM remains stationary.

The 320-185 includes Renishaw's UCCT5 5-axis controller and MCUlite-2 Joystick. Scale resolution is super small at 0.000002" (50 nanometers). The drive system is upgraded with strong motors and tachometers for rapid and crisp motion, and with perfectly tuned motion parameters. A taller Z-axis travel gives the probe more operating space and extra Y-axis travel leaves room for calibrations and automatic stylus changing.

The 320-185 is all about speed. It is capable of increasing throughput 2-3X over conventional CMM inspection cycles. It's like getting two CMMs for the price of one. The system is suited to factory floor applications and includes Helmel's legendary reliability and durability..

- CMM Manager Standard CAD DCC Software System

- DXF, IGES and STEP included

- TCR20 (6) Port Stylus Change Rack

- (2) additional Stylus Modules

- Rolling Side Cabinet for Controller and High Performance PC

- 01" Calibration Sphere with Certification

Specification

Type | MICROSTAR 320-185 HS | |

Measuring range | X-axis (mm) | 500 |

Y-axis (mm) | 750 | |

Z-axis (mm) | 450 | |

Dimension (mm) | W/L/H: 1040/1450/2310 | |

Resolution | 0.05µm | |

Repeatability | 0.00005” (1.27 μm) | |

Volumetric Accuracy | 0.00038” (9.65 μm) | |

Linear Accuracy | X-axis: 0.00012’’ (3 μm) | |

Y-axis: 0.00023’’ (5.8 μm) | ||

Z-axis: 0.00008’’ (2 μm) | ||

Utility | 120-230V~, 50-60Hz, 20A grounded main power supply | |