Standard: ISO 12048 ISO 2872 ASTM D4169 TAPPI T804 GB T4857-4 JIS Z212

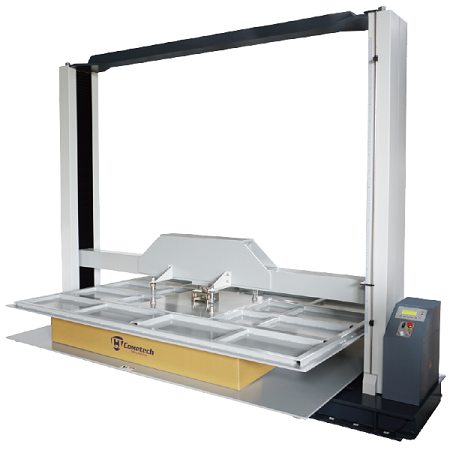

This model is designed for test large LCD screen packaging materials such as Styrofoam or other materials package container to proceed with whole carton compression strength test.Load measuring adopt three point bottom plate induction,large size and capacity can be customized to make servo system more accurate.

Besides, we also provide the software as optional purchase, the software can connection to control machine to proceed with various tests and analysis, it also can show test force and displacement of diagrams simultaneously during test.

Industry: Paper, packaging material, transport

Displayer

1. Adopted with 7- inch of TFT Color touch screen

2. Chinese, English, Japanese, Three different languages can be selected.

3. Data Display: Force, Stress, Torque, Displacement, Time

4. Test setting, can set test speed, test direction, automatic position return, breaking point machine stop.

5. Data analysis, can read the maximum force, internal force, breaking point force and so on.

6. Can be stand-alone calibration.

7.Various machine shutdown conditions setting (force, displacement, time, elongation).

8.Can be restored to the original factory state.

9.Unit selection can be Metric unit, Imperial units

10.Over-travel, overload protection and overtime machine stop

11.Can store up to 50 data, USB storage data function.

Software function:

1. Data sample rate faster can be set up to 1200 Hz

2. Operation method:Full-computerized control to run the test or Jog button control

3. Compatible with Window 7 /8 system

4. Software has multi-languages.

5. Interface for TCP/IP

6. Multi-curves display and real-time plot

7. Various units of measurement are available

8. Flexible form to manage database.

9. Free to name the data file.

10. Testing screen is selective to display data, graph at the same time.

11. Data processing: file saving, setting loading, report printing and data comparing.

12. Graph display: strain v.s. elongation, strain v.s. time and so on.

13. Tensile test, compression test, bending test, peel test…

14. Software protection: Overload, over -displacement ,over-time protection

15.Variety of test actions, ex.reciprocation, creep, hold tensile (compression), test pause, slip test, etc.

16.Modularization of specimen setting, providing easy to set specimen.

17.Modularization of test conditions to reduce artificial settingnegligence and error.

18.Key data capture, can set the upper and lower limits of test data specifications

19.Support multiple sets of I / O signals, increase testing mechanism

Technical Specification:

Model | DAS1043-M010 | DAB1010-M010 |

Test space | 2700(L)x1800(W)x1500(H) | 1800(L)x2600(W)x1600(H) |

Max.Capacity | 5000 kg(50kN) | 2000 kg(20kN) |

Unit switch | Force: gf, kgf, lbf, N, kN, ozf, tonf(SI), ton(long), tonf(short) | |

Force resolution | 31 bits | |

Force precision | 1/100,000 | |

Stroke resolution | 0.0001mm | |

Test speed | Low speed mode0.0001 ~ 0.95mm/min | |

Hardware safety protection | Up/down limit, emergency stop button protection | |

Motor | Servo motor | |

Feature | Upper compression platen with universal design matching with testing subjects that automatically adjust flat surface | |

PC-port | RJ45(TCP/IP) | |

power | Single phase200 ~ 240VAC | Single phase200 ~ 240VAC |

Dimension of machine | 2700(L)x2590(W)x2400(H) | 1800(L)x3261(W)x2600(H) |

Weight | Approx.2100kg | Approx.2600kg |