This instrument is suitable for use both in production lines where the operator has to be fast and efficient and can accurately control the test with the optional remote control unit and also laboratory environments where the advanced software lets users analyse the test data. Labtest allows full control of processing, filing, managing, and transmitting data to the company network, database, and performs many other functions.

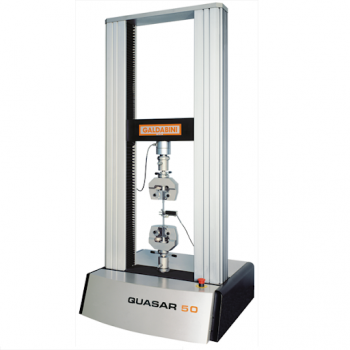

This Quasar frame has a flexible and modular construction. It can be equipped with various grips and fixtures, as well as extensometers, additional load cells, temperature chambers and many accessories, for a wide range of applications (tensile, compression, flexure, etc.). In addition, this user-friendly instrument can be fitted with additional load cells with lower capacities, providing the highest resolution and accuracy for microloads.

- Two-column rigid system with 1000 kN maximum capacity

- Suitable for metals, composites and other materials

- Stylish design and advanced features

- Ergonomic for intensive use

- Flexible and modular design for easy future expansion

- Key technical advantages include extremely high resolution of load and stroke readings, as well as minimum test speed of 0.0005 mm/min, for high performances and accurate results

- Manufactured by an ISO 9001 certified company

- Excellent price-to-quality ratio

| Capacity of frame and max allowed load | 1,000 kN (224,810 lbf) |

| Load cell nominal size (tensile & compression) | 1,000 kN |

| Standards met or exceeded | ISO 7500-1, ASTM E4, EN 10002-2, JIS B7721, GB/T 16825.1, DIN 51221, BS 1610 and other equivalent |

| Testing area depth | Unlimited |

| Power Rating | 3,000 W (7,000 W with optional item) |

| Machine weight (without accessories) | 3,700 Kg (8,160 lb) |

| Finishing | Silver RAL 9006 / Black RAL 9011 |

| PC interface | Ethercat (A dedicated Ethernet port on PC is required) |

| Noise level | < 72 db |

Dimensions

| Height | 3,057 mm |

| Width | 1,700 mm |

| Depth | 1,200 mm |