ElvaX ProSpector for Positive material identification

14:23 - 04/03/2021

X-Ray fluorescence handheld spectrometer is an ideal tool for PMI because of excellent precision for metals in wide concentration range (from ppm to 100%), fast results getting (several seconds) and nondestructive testing

ElvaX ProSpector for Regulatory Compliance

Advantages of the CMOS sensor in the GNR OES analyzer

ElvaX ProSpector implements fast and accurate PMI (Positive Material Identification) testing at any steps of alloy manufacturing or in-process alloy installation. Composition and grade of an alloy determine its durability, heat and corrosion resistance. Knowing alloy grade allows engineers, suppliers, plant workers to be sure in material properties.

ElvaX ProSpector rapidly and accurately identifies pure metals and alloy grades including, but not limited to:

- Magnesium alloys;

- Aluminum alloys;

- Titanium alloys;

- Stainless steels;

- Low alloy steels;

- Tool steels;

- Cobalt alloys;

- Nickel alloys;

- Copper alloys, brasses and bronzes;

- Zinc alloys;

- Solders;

- Precious alloys;

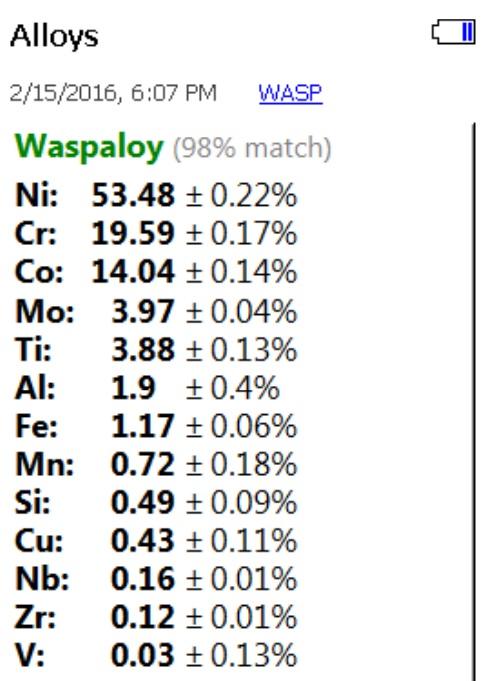

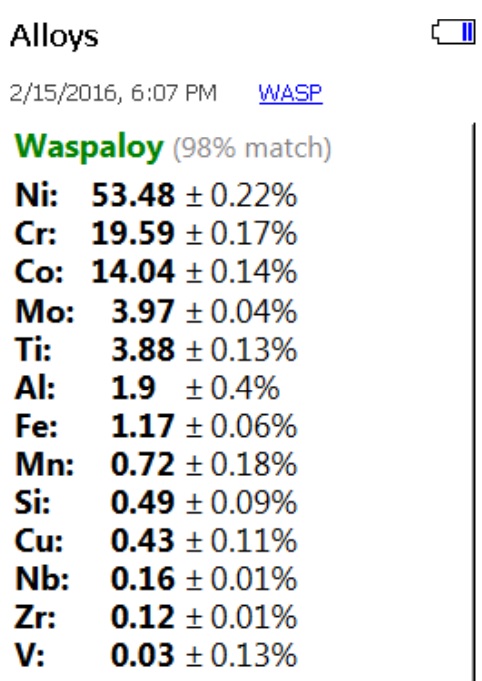

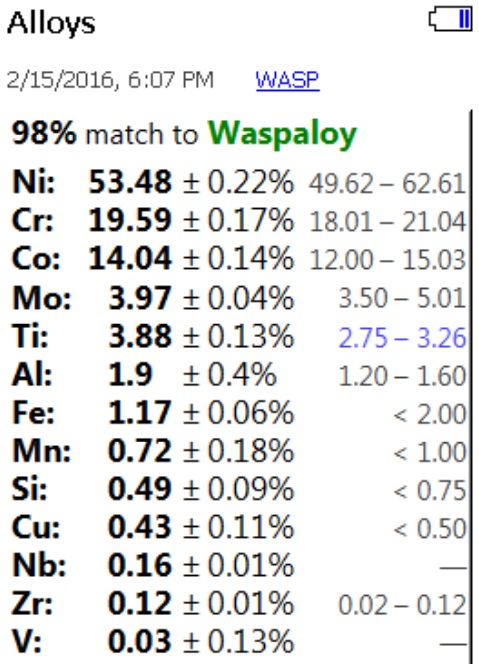

Analyzer software offers several testing modes:

- Composition. Displaying measured concentration of metals in unknown alloy.

- Grade ID. Software compares measured alloy with those saved in internal alloy library and shows the best matched alloy IDs.

Compare to alloy. Displaying both measured and certified concentrations of a specific alloy ID:

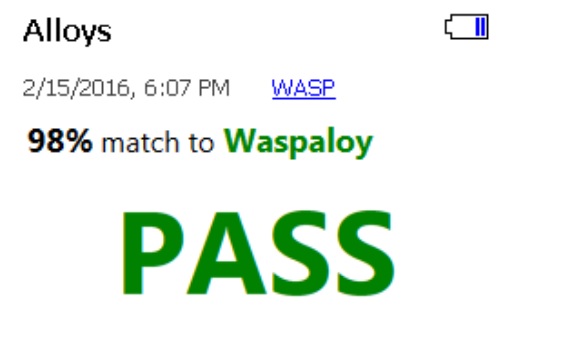

Pass/Fail. It is a useful mode for grading a specific alloy ID. Displaying “Pass” message when measured alloy fully complies alloy grade what you want, and “Fail” in other case.

Detailed specification of ProSpector 2 & ProSpector 3.

Alloy analysis requires minimal sample preparation. The most samples can be measured directly, but if any surface impurity or rust is presented, then analyzed surface must be polished.

Prospector has internal fundamental parameters calibration with specific settings for each alloy type (steels, copper alloys, nickel alloys, aluminum alloys and etc.). Software automatically selects settings for measured alloy class.

As one of the fastest XRF analyzer on the market, it is not surprising that the analysis time on ProSpector models does not exceed 20 seconds; Even in the most advanced models, the analysis time is only 5 seconds.

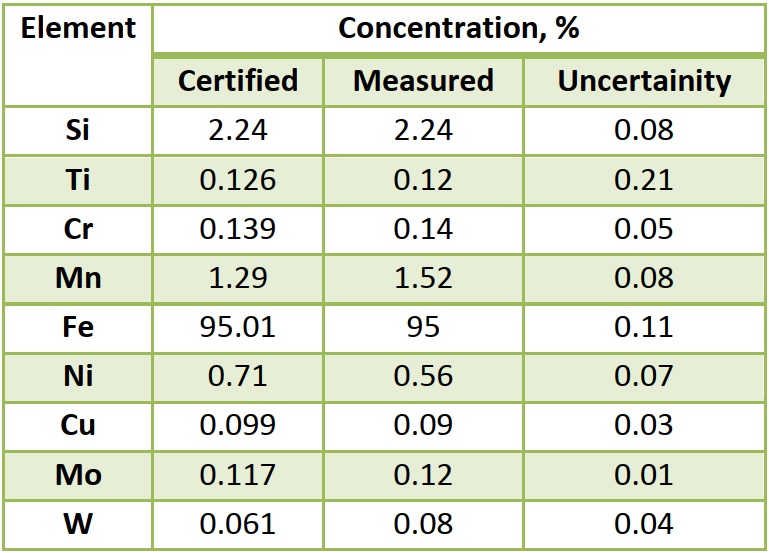

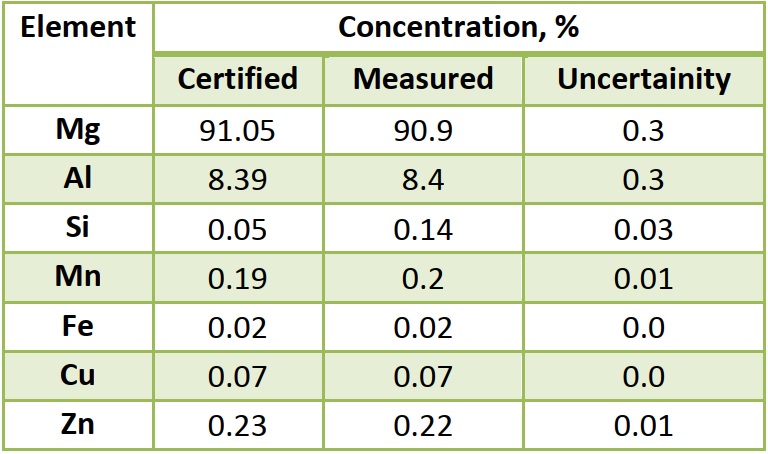

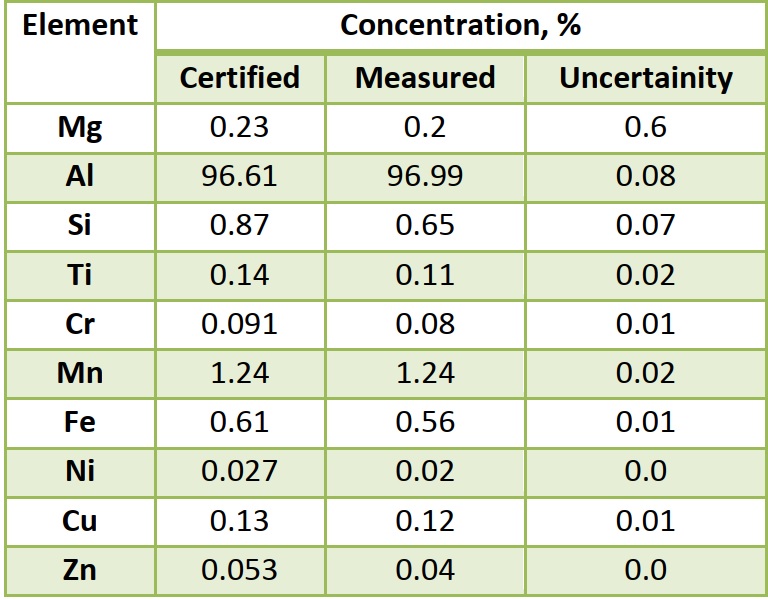

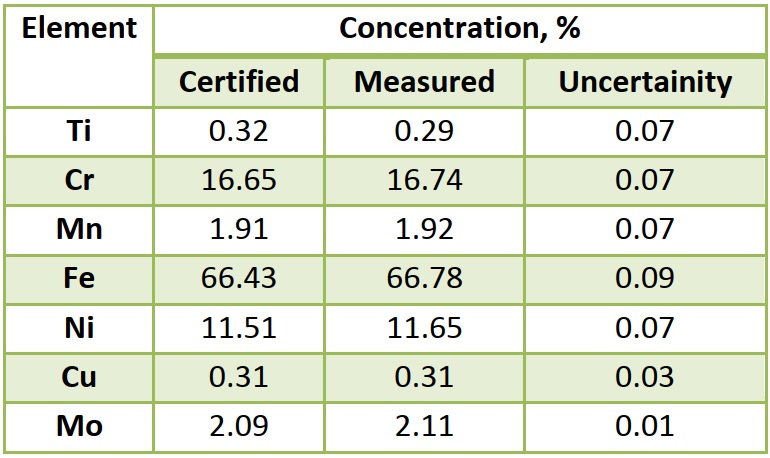

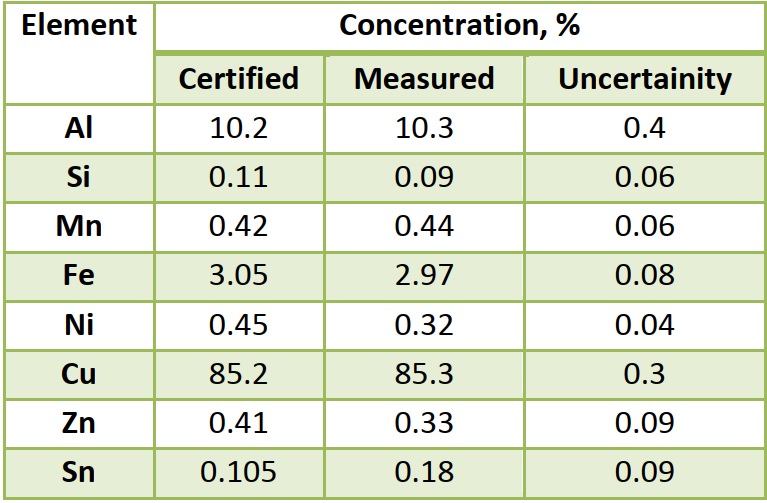

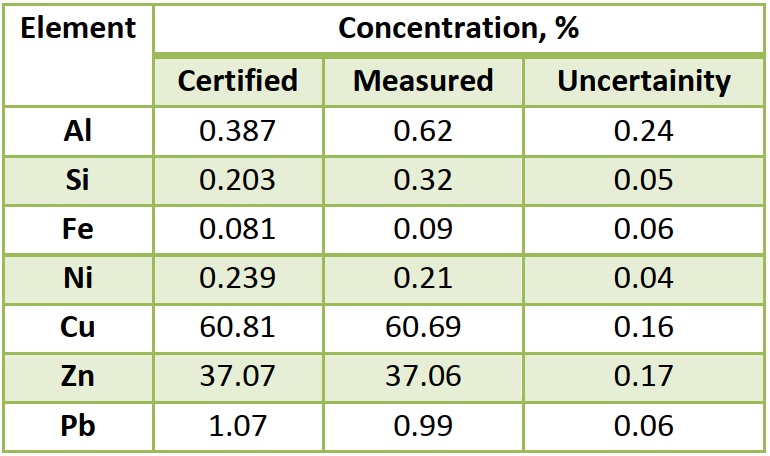

Let's see the analysis results on ProSpector and compare with the certified results:

Magnesium alloy AZ80A (UNS M11800):

Aluminum alloy grade 3030 (UNS A93030)

Stainless steel grade 316 (UNS S31600)

Low alloy steel AISI 9260

Bronze grade UNS C61900

Brass grade UNS C37000

Another important parameter of XRF device is the repeatability of the analysis. The SS316 was measured 10 times over a period of time. An average, standard deviation (Std Dev) and relative standard deviation (RSD) for Fe, Cr, Ni, Mo content was calculated from this data:

| No | Fe, % | Cr, % | Ni, % | Mo, % |

| 1 | 66,81 | 16,76 | 11,59 | 2,13 |

| 2 | 66,81 | 16,78 | 11,57 | 2,13 |

| 3 | 66,82 | 16,77 | 11,58 | 2,14 |

| 4 | 66,85 | 16,77 | 11,54 | 2,13 |

| 5 | 66,84 | 16,77 | 11,57 | 2,13 |

| 6 | 66,81 | 16,76 | 11,57 | 2,14 |

| 7 | 66,82 | 16,77 | 11,59 | 2,14 |

| 8 | 66,85 | 16,72 | 11,6 | 2,13 |

| 9 | 66,84 | 16,75 | 11,58 | 2,14 |

| 10 | 66,8 | 16,76 | 11,61 | 2,13 |

| Average | 66,825 | 16,761 | 11,58 | 2,134 |

| Std Dev | 0,016 | 0,011 | 0,014 | 0,005 |

| % RSD | 0,024 | 0,066 | 0,121 | 0,234 |

Conclusions:

- ElvaX ProSpector is an ideal instrument for positive material identification. It provides rapid, nondestructive and accurate analysis of different alloys.

- Obtained results indicate a good correlation between certified and measured concentration values.

- Because of extensive alloy grade library analyzer software can easily identify most international standard alloy IDs.

- Real-time data from handheld analyzer ElvaX ProSpector save a lot of time and money in alloy production industry, alloy installation and quality assurance.